If anyone is going down this path here is the coupler.

No worries! We’re hosting pi-top Sessions this Friday and it’s a Robotics Kit special, if you have time it might be interesting for you to come along as there’s a lot of other cool stuff being worked on - here’s the signup link, it’s at 5 PM GMT

Thanks - I’ve signed up for the event.

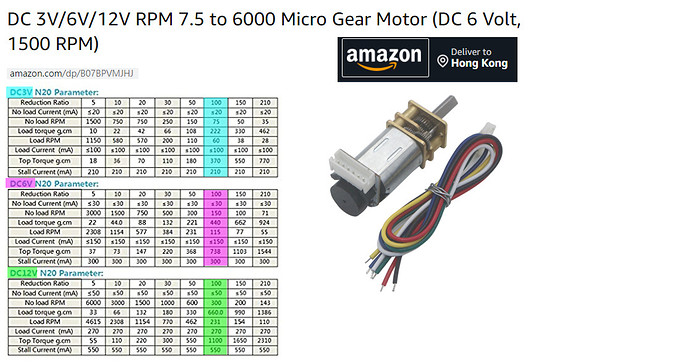

I have a couple of these little N20 gear motors lying in my junk box for some years now, collecting dust.

I once used Raspberry Pi and the bulky L298N motor driver board to control it and found it OK. Now I am thinking of using Rpi Pico with a smaller motor controller.

My long term objective is to make a robot car as small as possible.

Update 2021jun30hkt1130

I am thinking of using Rpi Pico to control the N20 motor, as described in the following Tom’s Hardware article.

How to Use Your Raspberry Pi Pico With DC Motors - By Les Pounder, TomsHardware, 2021jan30

Nice idea! I look forward to you sharing the progress on your build in the future

Thanks for your encouragement. I am going as slowly as possible, so to learn more things, and remember them harder. Cheers.

Isn’t the power supply from the battery underpowered - if one wanted to get maximum performance from these motors?

The pi-top lithium battery is rated in specs :

38.85 Watt-hour - (11.1V, 3500mAH)

Each of the n20 Gear is rated:

Voltage (Nominal) - 12V

Current (Stall @ 12VDC) - 1600mA

I’m assuming this means max possible wattage for each motor at max would be

12V x 1.6A = 19.2 watts

With two of these, we’re already at 38.4 watts.

With 4 motors it would be 76.8 watts of power… which is much more than the pi-top battery is rated.

How could we provide motors with enough juice to get maximum output possible?

Can’t you hook up an external power source via a USB C connector? I recall seeing posts about people taking on anker batteries.

Yup checked the rack sheet. You can draw an additional 15v.

Those are the pi-top [3] specs, pi-top [4] ones are here

In terms of the maximum power, you are mixing watt-hours and watts. I believe we limit the maximum current from the battery pack at 2C, which means 2 multiplied by the Ah rating. This would give a maximum current output from the pi-top [4] as 2.6 * 2 = 5.2A @ the battery voltage. Taking the nominal battery voltage to 7.4V you can get 38.48 watts

And yes you can hook up an external battery pack to the Expansion Plate’s USB-C connector, the motors would then draw directly from this power source

Well, the stall current of my N20 gear motor is only around 500mA. Can you give us a link of your N20 gear motor?

References

(1) N20 Gear Motor Spec - Amazon

Thanks for catching that and recalculating, I’m hopeful again for my use-case!

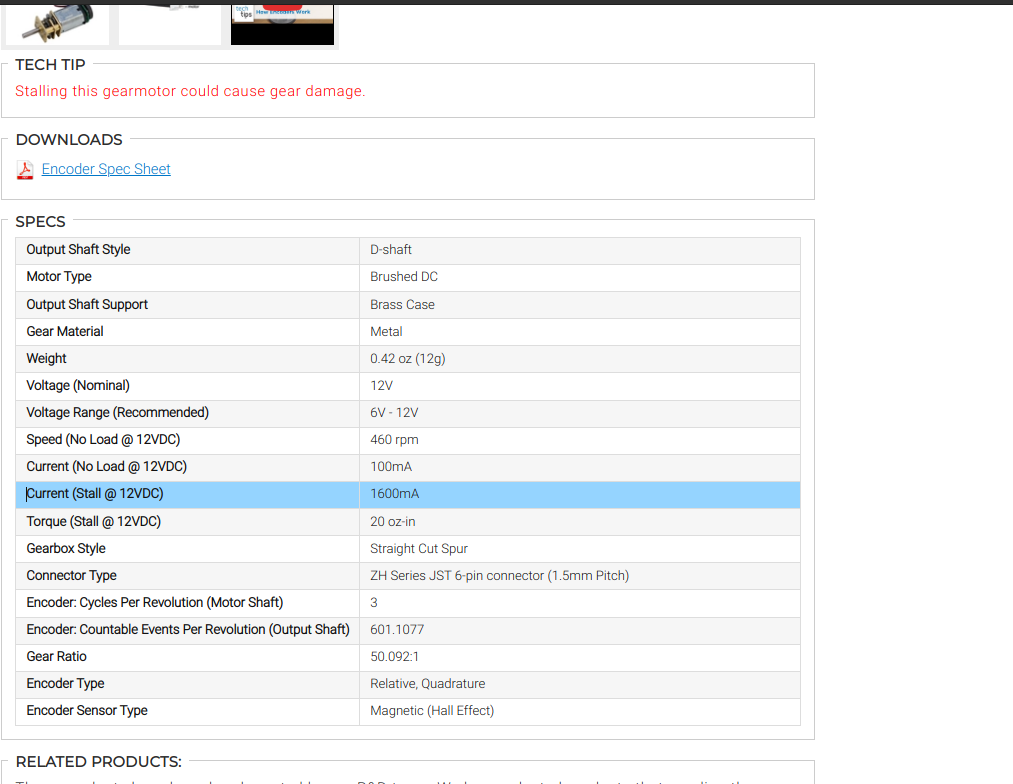

@tlfong01 Interesting, I’m using motors mentioned in Servocity from op post as reference -> https://www.servocity.com/460-rpm-micro-gear-motor-w-encoder/ .

My question was based of the specs shown below, but there’s good chance I’m just misunderstanding things…

Haven’t purchased these yet, but am planning to get two.

Good to know there are even more compatible options out there!

The Expansion Plate for pi-top [4] has inbuilt current limit protection so if using that you wouldn’t need to worry about motor damage. It’s quite funny that they call that motor “premium” - not entirely sure what’s premium about it…

The Encoder Cycles per Revolution stated is also incorrect, it should be 12 based on the other data (not 3)

Having said that, their video on how encoders work is excellent - definitely the best explanation I’ve ever seen!

I am skeptical about the stall current stated here, our robotics kit motor has 3-4x the torque and the stall current we have is 1000mA - so I wouldn’t worry too much about that current

Thank you for your link to the ServoCity’s N20 motor spec. I noticed that their N20 motors are professional, premium motors for RC, comparing to the consumer or toy class, and much cheaper/cost effective motors I am playing with.

In other words, you have not misunderstood anything, it is my ignorance on professional grade stuff. My apologies for misleading you.

One more friendly reminder is that we don’t usually stress motors to their extreme overload limit, or near the stall current limit.

You might have see the vendors warning on overloading motors. Actually I have permanently damaged a couple of N20 motor gear boxes these few years.

By the way, I usually go to the hobbyist motors expert Pololu to find useful information, comparison, and selection:

N20 Gear motor comparsion - Pololu

Another thing is that the Pololu N20 gear motors are max around 1.2W. So don’t expect high power for this mini gear power.

So I’m finally back to working on this project and I made a discovery I just wanted everyone to know. The hex couplings I linked above are a REALLY tight fit for the most recent robotmaster mecanum wheels. But a tiny amount of oil and a rubber mallet got the job done.

Sometimes hitting things is the answer.

Yeah I had the same problem actually, however your rubber mallet approach sounds quite sophisticated compared to my technique of slamming it onto a concrete floor with my hand

Proper Tools for a proper solution!