Hello Everyone,

I am writing this with regards to issues we are having with the Pi-Top4. We connected an MPU6050 to your GPIO pin slot but as a result, it burnt our sensor at 5V. We used this sensor on an Arduino beforehand and worked normally at 5V. Is it possible to connect an IMU to the GPIO slot and can you please if possible send a sample code for it? We do know there is an IMU in the expansion slot but is not consistent with the values we need.

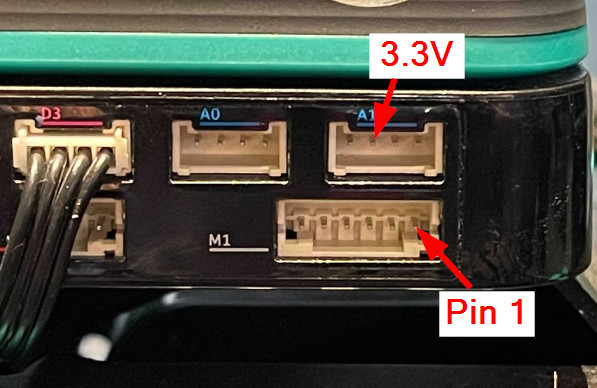

Regards to motor issues, we connect a REV Core Hex Motor to the Pi-Top4. But we connect a 2 Wire Power Cable and 4 Wire Sensor Cable to a Pi-Top4 Encoder Motor 6 Wire Cable. This does work but when wiring we get different results 1 option is to have the motor keep on accelerating but we can not control this due to the fact we do not know the correct wire connection for the Encoder Motor Wire. Even if we code it to go at a constant rate of 10 RPM it will accelerate until its max RPM. The second option when wiring is to go at a constant speed but at a slow RPM due to the motor using the Pi-Top4 specifications and us not wiring the 4 Wire Sensor Cable(Which we know is incorrect but is a solution.) Do you by any chance know which wires go into the Encoder Motor Wire? And if so do you have a Wire Diagram of the Encoder Motor 6 Wire on what each wire is for? And do we need any other components for the motor or sensor?

Thank you so much for the help in advance:)