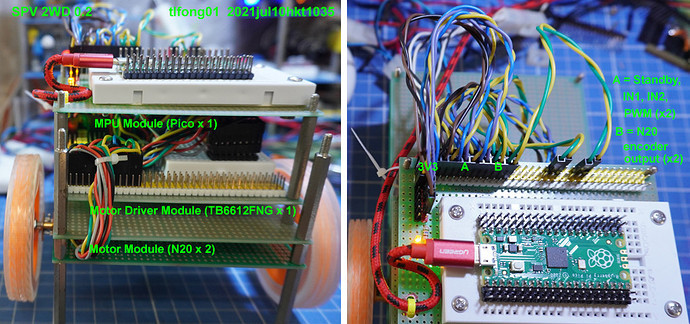

Now I have stacked all three modules to start python programming:

(1) Motor (N20 x 2),

(2) Motor Driver (TB66112FNG x 1)

(3) MCU (Pico x 1)

/ to continue, …

Now I have stacked all three modules to start python programming:

(1) Motor (N20 x 2),

(2) Motor Driver (TB66112FNG x 1)

(3) MCU (Pico x 1)

/ to continue, …

I am reading my old post to refresh memory on how to drive a DC motor. Last time I followed Tom’s Hardware tutorial to use Pico and MX1508 motor driver to drive only one motor TT130. Everything goes well.

This time I am modifying Tom’s Hardware’s python program to control my 2WD’s two N20 motors. I am also using the TB6612FNG motor controller. As I understand, for my simple applications, any common driver (L298N, DRV8833), and common motors TT130, N20) can be used.

Now I am testing moving only one N20 motor, and using Pico to control only IN1, IN2. The Standby and PWM signals are manually hardwired.

And the full program listing.

# Program Name

# move_dc_motor_v02.py - tlfong01 2021jul10hkt1132

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

# Configuration

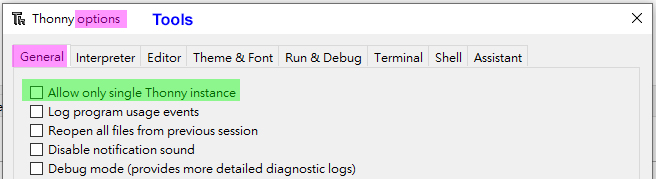

# Thonny 3.3.3, Windows 10 (64-bit), Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

# Intepreter

# Micropython (Rapsberry Pi Pico)

# DC Motor

# (a) TT130 DC3~6V DC Gear Motor - AliEXpress US$1

# https://www.aliexpress.com/item/32855311589.html

# (b) N20 Gear Motor

#

# DC Motor Driver

# (a) MX1508 2~10V, 1.5A, Dual H-Bridge DC Motor Driver - AliExpress US$1

# https://www.aliexpress.com/item/32688083107.html

# (b) TB6612FNG Dual DC Motor Driver

# Program Function

# Move DC motor forward, backward, and stop

# User Guide

# (a) Connect PWMA to High (Vcc)

# (b) Connect Standby to High

# (c) Run code to move motor forward, backward, and stop

import utime

from machine import Pin

motor1a = Pin(10, Pin.OUT)

motor1b = Pin(11, Pin.OUT)

def moveMotorForward():

motor1a.low()

motor1b.high()

def moveMotorBackward():

motor1a.high()

motor1b.low()

def stopMotor():

motor1a.low()

motor1b.low()

def test():

print(' Begin move motor test()')

moveMotorForward()

utime.sleep(1)

moveMotorBackward()

utime.sleep(1)

stopMotor()

print(' End test()')

for i in range(2):

print('Test ', i)

test()

# *** End of program ***

# *** Sample Output - tlfong01 2021jul01hkt1707

'''

>>> %Run -c $EDITOR_CONTENT

Test 0

Begin move motor test()

End test()

Test 1

Begin move motor test()

End test()

>>>

'''

Now I have written motor driver dictionaries and tested them OK, to make it easy to scale up 1WD to 2WD for two motors, and later 4WD for four motors. The program is fully listed below:

$ Program Name

$ move_dc_motor_v04.py - tlfong01 2021jul10hkt1558

$ Reference

$ Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

$ Making a Rpi Pico Based Smart Vehicle

$ Configuration

$ Thonny 3.3.3, Windows 10 (64-bit), Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

$ Intepreter

$ Micropython (Rapsberry Pi Pico)

$ DC Motor

$ (a) TT130 DC3~6V DC Gear Motor - AliEXpress US$1

$ https://www.aliexpress.com/item/32855311589.html

$ (b) N20 Gear Motor x 2

$

$ DC Motor Driver

$ (a) MX1508 2~10V, 1.5A, Dual H-Bridge DC Motor Driver - AliExpress US$1

$ https://www.aliexpress.com/item/32688083107.html

$ (b) TB6612FNG Dual DC Motor Driver

$ Program Function

$ Move two N20 DC motors forward, backward, and stop

$ User Guide

$ (a) Configuration

$ GP10 - Motor1 IN1

$ GP11 - Motor1 IN2

$ GP12 - Motor1 PWMA

$ GP13 - Motor2 IN1

$ GP14 - Motor2 IN2

$ GP15 - Motor2 PWMB

$ GP9 - Motor1, 2, Standby

$ (b) Run program to move in sequence, two motors forward, backward, and stop

import utime

from machine import Pin

$ Configuration

multiMotorDriverDict01 = {

‘Title’ : ‘Motor Driver Dict For 4WD’,

‘STBY’ : 9,

‘1’ : {‘IN1’ : 10,

‘IN2’ : 11,

‘PWM’ : 12,

},

‘2’ : {‘IN1’ : 13,

‘IN2’ : 14,

‘PWM’ : 15,

},

‘3’ : {‘IN1’ : 0,

‘IN2’ : 0,

‘PWM’ : 0,

},

‘4’ : {‘IN1’ : 0,

‘IN2’ : 0,

‘PWM’ : 0,

},

}

multiMotorDriverDictDict = {

‘1’: multiMotorDriverDict01,

‘1’: multiMotorDriverDict01,

}

def setupMotor(multiMotorDriverDictDictNum, motorDriverNum):

motorDriverDict = multiMotorDriverDictDict[str(multiMotorDriverDictDictNum)]

in1PinNum = motorDriverDict[str(motorDriverNum)]['IN1']

in2PinNum = motorDriverDict[str(motorDriverNum)]['IN2']

pwmPinNum = motorDriverDict[str(motorDriverNum)]['PWM']

print('In1PinNum =', in1PinNum)

print('In2PinNum =', in2PinNum)

print('pwmPinNum =', pwmPinNum)

in1Pin = Pin(in1PinNum, Pin.OUT)

in2Pin = Pin(in2PinNum, Pin.OUT)

pwmPin = Pin(pwmPinNum, Pin.OUT)

picoMotorDriverControlPinDict = {'IN1': in1Pin, 'IN2': in2Pin, 'PWM': pwmPin}

return picoMotorDriverControlPinDict

def moveMotorForward(motorDriverDict):

in1Pin = motorDriverDict[‘IN1’]

in2Pin = motorDriverDict[‘IN2’]

pwmPin = motorDriverDict[‘PWM’]

in1Pin.low()

in2Pin.high()

pwmPin.high()

return

def moveMotorBackward(motorDriverDict):

in1Pin = motorDriverDict[‘IN1’]

in2Pin = motorDriverDict[‘IN2’]

pwmPin = motorDriverDict[‘PWM’]

in1Pin.high()

in2Pin.low()

pwmPin.high()

return

def stopMotor(motorDriverDict):

in1Pin = motorDriverDict[‘IN1’]

in2Pin = motorDriverDict[‘IN2’]

pwmPin = motorDriverDict[‘PWM’]

in1Pin.low()

in2Pin.low()

pwmPin.high()

return

$ Main $

$ Test Motors #1, #2

motorDictDictNum = 1

motorNumList = [1, 2]

for motorNum in motorNumList:

motorDriverDict = setupMotor(motorDictDictNum, motorNum)

moveMotorForward(motorDriverDict)

utime.sleep(1)

moveMotorBackward(motorDriverDict)

utime.sleep(1)

stopMotor(motorDriverDict)

$ End of program

Next step is writing functions to turn vehicle right and left.

/ to continue, …

The turn right/left functions are easy to write and test. The ‘#’ symbol crashes with the forum editor. So I replaced the symbol to ‘$’

$ Program Name

$ move_dc_motor_v08.py - tlfong01 2021jul10hkt1625

$ Reference

$ Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

$ https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

$ Configuration

$ Thonny 3.3.3, Windows 10 (64-bit), Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port $4

$ Intepreter

$ Micropython (Rapsberry Pi Pico)

$ DC Motor

$ (a) TT130 DC3~6V DC Gear Motor - AliEXpress US$1$

$ (b) N20 Gear Motor x 2

$

$ DC Motor Driver

$ (a) MX1508 2~10V, 1.5A, Dual H-Bridge DC Motor Driver - AliExpress US$1

$ https://www.aliexpress.com/item/32688083107.html

$ (b) TB6612FNG Dual DC Motor Driver

$ Program Functions

$ (a) Move two N20 DC motors forward, backward, and stop.

$ (b) Move left motor forward, right motor backward, so to turn vehicle right.

$ (c) Similarly, left motor backward, right motor forward, so to turn vehicle left

$ User Guide

$ (a) Configuration

$ GP10 - Motor1 IN1

$ GP11 - Motor1 IN2

$ GP12 - Motor1 PWMA

$ GP13 - Motor2 IN1

$ GP14 - Motor2 IN2

$ GP15 - Motor2 PWMB

$ GP9 - Motor1, 2, Standby

$ (b) Run program to move in sequence, two motors forward, backward, and stop

import utime

from machine import Pin

$ Configuration

multiMotorDriverDict01 = {

'Title' : 'Motor Driver Dict For 4WD',

'STBY' : 9,

'1' : {'IN1' : 10,

'IN2' : 11,

'PWM' : 12,

},

'2' : {'IN1' : 13,

'IN2' : 14,

'PWM' : 15,

},

'3' : {'IN1' : 0,

'IN2' : 0,

'PWM' : 0,

},

'4' : {'IN1' : 0,

'IN2' : 0,

'PWM' : 0,

},

}

multiMotorDriverDictDict = {

'1': multiMotorDriverDict01,

'1': multiMotorDriverDict01,

}

$ ***

def setupMotor(multiMotorDriverDictDictNum, motorDriverNum):

motorDriverDict = multiMotorDriverDictDict[str(multiMotorDriverDictDictNum)]

in1PinNum = motorDriverDict[str(motorDriverNum)]['IN1']

in2PinNum = motorDriverDict[str(motorDriverNum)]['IN2']

pwmPinNum = motorDriverDict[str(motorDriverNum)]['PWM']

print('In1PinNum =', in1PinNum)

print('In2PinNum =', in2PinNum)

print('pwmPinNum =', pwmPinNum)

in1Pin = Pin(in1PinNum, Pin.OUT)

in2Pin = Pin(in2PinNum, Pin.OUT)

pwmPin = Pin(pwmPinNum, Pin.OUT)

picoMotorDriverControlPinDict = {'IN1': in1Pin, 'IN2': in2Pin, 'PWM': pwmPin}

return picoMotorDriverControlPinDict

def moveMotorForward(motorDriverDict):

in1Pin = motorDriverDict['IN1']

in2Pin = motorDriverDict['IN2']

pwmPin = motorDriverDict['PWM']

in1Pin.low()

in2Pin.high()

pwmPin.high()

return

def moveMotorBackward(motorDriverDict):

in1Pin = motorDriverDict['IN1']

in2Pin = motorDriverDict['IN2']

pwmPin = motorDriverDict['PWM']

in1Pin.high()

in2Pin.low()

pwmPin.high()

return

def stopMotor(motorDriverDict):

in1Pin = motorDriverDict['IN1']

in2Pin = motorDriverDict['IN2']

pwmPin = motorDriverDict['PWM']

in1Pin.low()

in2Pin.low()

pwmPin.high()

return

def turnVehicleRight(motorDriverDictLeft, motorDriverDictRight):

moveMotorForward(motorDriverDictLeft)

moveMotorBackward(motorDriverDictRight)

return

def turnVehicleLeft(motorDriverDictLeft, motorDriverDictRight):

moveMotorForward(motorDriverDictRight)

moveMotorBackward(motorDriverDictLeft)

return

$ Main test functions

def testSequentiallyMoveTwoMotorsForwardBackwardAndStop():

motorDictDictNum = 1

motorNumList = [1, 2]

for motorNum in motorNumList:

motorDriverDict = setupMotor(motorDictDictNum, motorNum)

moveMotorForward(motorDriverDict)

utime.sleep(1)

moveMotorBackward(motorDriverDict)

utime.sleep(1)

stopMotor(motorDriverDict)

return

def testTurnVehicleRightOneSecondThenLeftOneSecond():

motorDictDictNum = 1

leftMotorDriverDict = setupMotor(motorDictDictNum, 1)

rightMotorDriverDict = setupMotor(motorDictDictNum, 2)

turnVehicleRight(leftMotorDriverDict, rightMotorDriverDict)

utime.sleep(2)

turnVehicleLeft(leftMotorDriverDict, rightMotorDriverDict)

utime.sleep(2)

stopMotor(leftMotorDriverDict)

stopMotor(rightMotorDriverDict)

$ Main $

$ testSequentiallyMoveTwoMotorsForwardBackwardAndStop()

testTurnVehicleRightOneSecondThenLeftOneSecond()

$ End of program

Now that I have completed the point to point wiring of Pico GB6~9 pins to the two N20 encoder outputs. Next step is to write a Pico microPython to do all motor control in software.

I forgot I need first to do some calibration of the N20 motor encoder signal vs speed (rpm) off line (ie no Pico software). So I disconnect the Pico GP signal and use manual jumper wires to give the control signals, and use my 50MHz scope to check the motor speed. as shown below.

Now I am analysing the N20 Motor 1 Encoder signal Output 1, and see if we can calculate the motor speed from this signal. Avery rough formula is 600uS ~= 30 rpm. Next step is is see how to do the time stamping use micro python.

MicroPython utime – time related functions

https://docs.micropython.org/en/latest/library/utime.html

Description - The utime module provides functions for getting the current time and date, measuring time intervals, and for delays.

I read the docs for utime and found it similar to Thonny python, except a little bet smaller. I found user friendly examples on how to use the utime (now I know the “u” of utime means “micro”!  ). One good such example has limit of time calculation less than 500us, but N20 motor’s timing is of the order of 600uS, in other words, just NOT make. I am too lazy to modify my demo programs to it my N20 applications. So lazy me go to Tom’s Hardware for help. I remember Tom;s Hardware has developed a big number of tutorials for newbies, as listed below.

). One good such example has limit of time calculation less than 500us, but N20 motor’s timing is of the order of 600uS, in other words, just NOT make. I am too lazy to modify my demo programs to it my N20 applications. So lazy me go to Tom’s Hardware for help. I remember Tom;s Hardware has developed a big number of tutorials for newbies, as listed below.

Tom’s Hardware Tutorials on Rpi Pico

In the relatively short time that the Pico has been on the market, the Raspberry Pi community has already developed a ton of resources. At Tom’s Hardware, we’ve been publishing our fair share of Pico how-tos, which you can find below.

Tutorial #7 on DC motors is useful for my N20 motor 2WD project here. There is also a useful demo program on the use of buttons. The critical statements are highlighted in pink.

Resuming Long Stalled SPV (Smart Pico Vehicle) Project

Part 1

This project has be stalled for over a month, and I have forgotten what I did last time. So I need now to refresh my memory. The first thing is to make sure the basic Pico hardware still running OK. My first test procedure is to run the “toggle system led program”. Luckily all looks well. Below is the updated toggle led program, with sample output.

# Program Name

# toggle_pico_system_led_v04.py - tlfong01 2021aug16hkt1606

# Configuration

# Thonny 3.3.3, Acer Intel CORE i5 Chinese Windows 10 (64-bit), Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

# Intepreter

# Micropython (Rapsberry Pi Pico)

# Program Function

# Toggle Pico system LED at GPIO pin 15 (run program to switch on LED, run again to switch off)

# User Guide

# Run code to toggle LED from On to Off or Off to On

from machine import Pin

systemLed = Pin(25, Pin.OUT)

print('Testing Toggling Pcio System LED, v0.4 tlfong01 2021aug16hkt1613')

systemLed.toggle()

# END

# Sample Output - tlfong01 2021aug16hkt1614

'''

>>> %Run -c $EDITOR_CONTENT

Testing Toggling Pcio System LED, v0.4 tlfong01 2021aug16hkt1613

>>> %Run -c $EDITOR_CONTENT

Testing Toggling Pcio System LED, v0.4 tlfong01 2021aug16hkt1613

>>>

'''

Part 2 - Checking the 2WD Wiring

I vaguely remember that I first tested one TT130 toy motor with the very simple MX1508 driver, as described by the Tom’s Hardware tutorial. Then I moved on to used TB6616 motr driver, with two N20 motors with speed encoders. I vaguely remember that I used Pico GPIO to read the one of the two encoder output signals, and got a rough idea of the motor speed vs encoder signal periods. So I need to resume from this point. But before that, I need to make sure the motor driver and motor can still move. First step is check out the hardware setup and wiring, and run the basic test program.

Actually I forgot the details of the hardware. So I read my old post to refresh my memory: Making a Rpi Pico Based Smart Vehicle.

The following image is a good memory refresher:

Part 3 - Manual Jumper Wire Motor Moving Testing

Now I am using the following cheat sheet to refresh my memory on how to use jumper wires to off line testing moving motors

To move Motor 1 CW, Motor 2 CCW, I am using the following conifg/wiring

IN1, IN2 (Yellow, Blue) to Low High or High Low

PWM (Purple) = High

StdBy (Brown) = High

Part 4 - Using MicroPython to test moving motors

Now I am using the following Pico MicroPython program is move one motor forward, backward, and stop, and found everything OK.

# Program Name

# move_one_motor_v01.py - tlfong01 2021aug16hkt2218

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

# Configuration

# Thonny 3.3.3, Windows 10 (64-bit), Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

# Intepreter

# Micropython (Rapsberry Pi Pico)

# DC Motor

# (a) TT130 DC3~6V DC Gear Motor - AliEXpress US$1

# https://www.aliexpress.com/item/32855311589.html

# (b) N20 Gear Motor

#

# DC Motor Driver

# (a) MX1508 2~10V, 1.5A, Dual H-Bridge DC Motor Driver - AliExpress US$1

# https://www.aliexpress.com/item/32688083107.html

# (b) TB6612FNG Dual DC Motor Driver

# Program Function

# Move DC motor forward, backward, and stop

# User Guide

# (a) Connect PWMA (purple), PWMB (purple) to High (Vcc)

# (b) Connect Standby (brown) to High

# (c) Run program to move motor forward, backward, and stop

import utime

from machine import Pin

motor1a = Pin(10, Pin.OUT)

motor1b = Pin(11, Pin.OUT)

def moveMotorForward():

motor1a.low()

motor1b.high()

def moveMotorBackward():

motor1a.high()

motor1b.low()

def stopMotor():

motor1a.low()

motor1b.low()

def test():

print(' Begin move motor test()')

moveMotorForward()

utime.sleep(1)

moveMotorBackward()

utime.sleep(1)

stopMotor()

print(' End test()')

for i in range(2):

print('Test ', i)

test()

# *** End of program ***

# *** Sample Output - tlfong01 2021jul01hkt1707

'''

>>> %Run -c $EDITOR_CONTENT

Test 0

Begin move motor test()

End test()

Test 1

Begin move motor test()

End test()

>>>

'''

Part 5 - Moving two motors

Now that my little demo microPython program moving one N20 motor goes well, I am now upgrading it to move two motors. Now I have a problem of mixing up the getting complicated jumper wires, and therefore find it difficult to do troubleshooting. So I need to do some proper documentation, starting with the photo below.

Now the time has come to use Pico MicroPython to move two motors. The following program is tested OK.

# Program Name

# move_two_motors_v05.py - tlfong01 2021aug17hkt1607

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

#

# Configuration

# Acer Intel COIRE i5 PC Chinese Windows 10 (64-bit), Thonny 3.3.3, Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

#

# Thonny MicroPython Intepreter

# Micropython (Rapsberry Pi Pico)

# DC Motor

# N20 1:48 6V DC Gear Motor with quadrature encoder signals A, B

#

# DC Motor Driver

# TB6612FNG Dual DC Motor Driver

# Program Function

# Move Two DC motors forward, backward, and stop

# User Guide

# (a) Connect PWMA (purple), PWMB (purple) to High (Vcc)

# (b) Connect Standby (brown) to High (Vcc)

# (c) Pico GP 10, 11 (Blk, Bwn) to Motor Driver AIN1, AIN2 (Yel, Blu)

# (d) Pico GP 12, 13 (Red, Orn) to Motor Driver BIN1, BIN2 (Yel, Blu)

# (c) Run program to move motor forward, backward, and stop

import utime

from machine import Pin

motorDict01 = {

'1': {'IN1': 10, 'IN2': 11},

'2': {'IN1': 12, 'IN2': 13},

'3': {'IN1': 0, 'IN2': 0},

'4': {'IN1': 0, 'IN2': 0},

}

motorDictDict = {

'1': motorDict01,

'2': motorDict01,

}

def setupMotor(motorDictNum, motorNum):

motorDict = motorDictDict[str(motorDictNum)]

motorIn1 = Pin(motorDict[str(motorNum)]['IN1'], Pin.OUT)

motorIn2 = Pin(motorDict[str(motorNum)]['IN2'], Pin.OUT)

motorInList = [motorIn1, motorIn2]

return motorInList

def moveMotorForward(motorDictNum, motorNum):

motorInList = setupMotor(motorDictNum, motorNum)

motorInList[0].high()

motorInList[1].low()

return motorInList

def moveMotorBackward(motorDictNum, motorNum):

motorInList = setupMotor(motorDictNum, motorNum)

motorInList[0].low()

motorInList[1].high()

return motorInList

def moveMotorStop(motorDictNum, motorNum):

motorInList = setupMotor(motorDictNum, motorNum)

motorInList[0].low()

motorInList[1].low()

return motorInList

# *** Tests ***

moveMotorForward(motorDictNum = 1, motorNum = 1)

utime.sleep(1)

moveMotorBackward(motorDictNum = 1, motorNum = 1)

utime.sleep(1)

moveMotorStop(motorDictNum = 1, motorNum = 1)

moveMotorForward(motorDictNum = 1, motorNum = 2)

utime.sleep(2)

moveMotorBackward(motorDictNum = 1, motorNum = 2)

utime.sleep(2)

moveMotorStop(motorDictNum = 1, motorNum = 2)

# *** End of program ***

# *** Sample Output - tlfong01 2021jul01hkt1707

'''

'''

Part 6 - Moving two motors with program controlling StandBy and PWM

The following program moving two motor and program control StandBy and PWM is tested OK.

# Program Name

# move_two_motors_v09.py - tlfong01 2021aug17hkt2014

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

#

# Configuration

# Acer Intel COIRE i5 PC Chinese Windows 10 (64-bit), Thonny 3.3.3, Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

#

# Thonny MicroPython Intepreter

# Micropython (Rapsberry Pi Pico)

# DC Motor

# N20 1:48 6V DC Gear Motor with quadrature encoder signals A, B

#

# DC Motor Driver

# TB6612FNG Dual DC Motor Driver

# Program Function

# Move Two DC motors forward, backward, and stop

# User Guide

# (a) Connect PWMA (purple), PWMB (purple) to High (Vcc)

# (b) Connect Standby (brown) to High (Vcc)

# (c) Pico GP 10, 11 (Blk, Bwn) to Motor Driver AIN1, AIN2 (Yel, Blu)

# (d) Pico GP 12, 13 (Red, Orn) to Motor Driver BIN1, BIN2 (Yel, Blu)

# (c) Run program to move motor forward, backward, and stop

import utime

from machine import Pin

driverDict01 = {

'Title' : 'TB6612FNG Dual DC Motor Driver',

'STANDBY' : 5,

'1': {'IN1': 10, 'IN2': 11, 'PWM' : 3, 'ENCODE': 14},

'2': {'IN1': 12, 'IN2': 13, 'PWM' : 4, 'ENCODE': 15},

'3': {'IN1': 0, 'IN2': 0, 'PWM' : 0},

'4': {'IN1': 0, 'IN2': 0, 'PWM' : 0},

}

driverDictDict = {

'1': driverDict01,

'2': driverDict01,

}

def setupDriver(driverDictNum):

driverDict = driverDictDict[str(driverDictNum)]

standBy = Pin(driverDict['STANDBY'], Pin.OUT)

standBy.high()

return

def setupMotor(driverDictNum, motorNum):

driverDict = driverDictDict[str(driverDictNum)]

motorIn1 = Pin(driverDict[str(motorNum)]['IN1'], Pin.OUT)

motorIn2 = Pin(driverDict[str(motorNum)]['IN2'], Pin.OUT)

motorPwm = Pin(driverDict[str(motorNum)]['PWM'], Pin.OUT)

motorControlPinList = [motorIn1, motorIn2, motorPwm]

return motorControlPinList

def moveMotorForward(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].low()

motorControlPinList[1].high()

motorControlPinList[2].high()

return

def moveMotorBackward(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].high()

motorControlPinList[1].low()

motorControlPinList[2].high()

return

def moveMotorStop(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].low()

motorControlPinList[1].low()

motorControlPinList[2].high()

return

# *** Motor Test Functions ***

def motorTest01(driverDictNum, motorNum):

# *** Setup Driver ***

setupDriver(driverDictNum)

# *** Move motor forward ***

moveMotorForward(driverDictNum, motorNum)

utime.sleep(1)

# *** Move motor backward ***

moveMotorBackward(driverDictNum, motorNum)

utime.sleep(1)

# *** Move motor stop ***

moveMotorStop(driverDictNum, motorNum)

return

# *** Main Tests ***

# Setup motor driver, Move Motor 1 forward, backward, stop

motorTest01(driverDictNum = 1, motorNum = 1)

# Setup motor driver, Move Motor 2 forward, backward, stop

motorTest01(driverDictNum = 1, motorNum = 2)

# *** End of program ***

# *** Sample Output - tlfong01 2021jul01hkt1707

'''

>>> %Run -c $EDITOR_CONTENT

'''

Part 6 - Reading Encoder Signals

The following program give N20 1:100 gear speed of around 400rpm

# Program Name

# measure_motor_speed_v09.py - tlfong01 2021aug18hkt1120

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

#

# Configuration

# Acer Intel COIRE i5 PC Chinese Windows 10 (64-bit), Thonny 3.3.3, Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

#

# Thonny MicroPython Intepreter

# Micropython (Rapsberry Pi Pico)

#

# DC Motor

# N20 1:100 6V DC Gear Motor with quadrature encoder signals A, B

# N20 Gear Motor Spec (6V gear 1:100 no load speed = 300 rpm (https://www.pololu.com/search/compare/173)

#

# DC Motor Driver

# TB6612FNG Dual DC Motor Driver

# Program Function

# Measure speed of DC motor N20 with quadrature encoder

import utime

from machine import Pin

driverDict01 = {

'Title' : 'TB6612FNG Dual DC Motor Driver',

'STANDBY' : 5,

'1': {'IN1': 10, 'IN2': 11, 'PWM' : 3, 'ENCODE': 14},

'2': {'IN1': 12, 'IN2': 13, 'PWM' : 4, 'ENCODE': 15},

'3': {'IN1': 0, 'IN2': 0, 'PWM' : 0},

'4': {'IN1': 0, 'IN2': 0, 'PWM' : 0},

}

driverDictDict = {

'1': driverDict01,

'2': driverDict01,

}

def setupDriver(driverDictNum):

driverDict = driverDictDict[str(driverDictNum)]

standBy = Pin(driverDict['STANDBY'], Pin.OUT)

standBy.high()

return

def setupMotor(driverDictNum, motorNum):

driverDict = driverDictDict[str(driverDictNum)]

motorIn1 = Pin(driverDict[str(motorNum)]['IN1'], Pin.OUT)

motorIn2 = Pin(driverDict[str(motorNum)]['IN2'], Pin.OUT)

motorPwm = Pin(driverDict[str(motorNum)]['PWM'], Pin.OUT)

motorEncode = Pin(driverDict[str(motorNum)]['ENCODE'], Pin.IN, Pin.PULL_DOWN)

motorControlPinList = [motorIn1, motorIn2, motorPwm, motorEncode]

return motorControlPinList

def moveMotorForward(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].low()

motorControlPinList[1].high()

motorControlPinList[2].high()

return

def moveMotorBackward(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].high()

motorControlPinList[1].low()

motorControlPinList[2].high()

return

def moveMotorStop(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

motorControlPinList[0].low()

motorControlPinList[1].low()

motorControlPinList[2].high()

return

def readMotorEncodeValue(driverDictNum, motorNum):

motorControlPinList = setupMotor(driverDictNum, motorNum)

encodeValue = motorControlPinList[3].value()

return encodeValue

# *** Motor Test Functions ***

def testMoveMotor01(driverDictNum, motorNum):

# *** Setup Driver ***

setupDriver(driverDictNum)

# *** Move motor forward ***

moveMotorForward(driverDictNum, motorNum)

utime.sleep(1)

# *** Move motor backward ***

moveMotorBackward(driverDictNum, motorNum)

utime.sleep(1)

# *** Move motor stop ***

moveMotorStop(driverDictNum, motorNum)

return

def testReadMotorEncodeValue01(driverDictNum, motorNum):

# *** Setup Driver ***

setupDriver(driverDictNum)

# *** Read motor encode value ***

print('Move motor by hand and read encode value every second, ...')

for secondCount in range(100):

encodeValue = readMotorEncodeValue(driverDictNum, motorNum)

print(' motor encode value =', encodeValue)

utime.sleep(1)

return

def testReadMotorEncodeValue02(driverDictNum, motorNum):

# *** Setup Driver ***

setupDriver(driverDictNum)

# *** Move motor forward ***

moveMotorForward(driverDictNum, motorNum)

# *** Read motor encode value ***

print('Move motor by hand and read encode value every second, ...')

for secondCount in range(100):

encodeValue = readMotorEncodeValue(driverDictNum, motorNum)

print(' motor encode value =', encodeValue)

utime.sleep(1)

return

def testMeasureMotorSpeed01(driverDictNum, motorNum):

# *** Setup Driver ***

setupDriver(driverDictNum)

# *** Move motor forward ***

moveMotorForward(driverDictNum, motorNum)

# *** Measure Motor Speed ***

# *** Start counting 10 revolutions ***

usTicks1 = utime.ticks_us()

# *** Find lapse time of 100 revolutions ***

revCount = 0

while revCount < 10:

if readMotorEncodeValue(driverDictNum, motorNum) == 0:

revCount = revCount + 1

utime.sleep(0.000001)

usTicks2 = utime.ticks_us()

rev10Us = utime.ticks_diff(usTicks2, usTicks1)

revUs = int(rev10Us / 10)

rps = int(1000000 / revUs)

rpmRaw = int(rps * 60)

rpmGear100 = int(rpmRaw / 100)

print('revUs =', revUs)

print('rps =', rps)

print('rpm raw =', rpmRaw)

print('rpm 100 =', rpmGear100)

moveMotorStop(driverDictNum, motorNum)

return

# *** Main Tests ***

# *** Test move motor forward, backward, stop ***

# testMoveMotor01(driverDictNum = 1, motorNum = 1)

# testMoveMotor01(driverDictNum = 1, motorNum = 2)

# *** Test measure motor speed ***

testMeasureMotorSpeed01(driverDictNum = 1, motorNum = 1)

# ***

#moveMotorStop(driverDictNum = 1, motorNum = 1)

# *** End of program ***

# *** Sample Output - tlfong01 2021aug18hkt1120

'''

>>> %Run -c $EDITOR_CONTENT

revUs = 1250

rps = 800

rpm raw = 48000

rpm 100 = 480

>>>

'''

Part 7 - Using PWM to control speed of N20 Motor

Now I have written the following program to test basic PWM functions. I need to use my scope to display the 1kHz, 50% duty cycle waveform, before trying to use this PWM signal to control the speed of the N20 motor.

# *** PWM Functions ***

def setupPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

motorDriverDict = motorDriverDictDict[str(motorDriverDictNum)]

pwmPinNum = motorDriverDict[str(motorNum)]['PWM']

motorPwm = PWM(Pin(pwmPinNum))

motorPwm.freq(pwmFreq)

motorPwm.duty_u16(int(65536 / 100) * dutyCycle)

print('PWM freq (Hz) =', motorPwm.freq())

print('PWM duty (%) =', int((motorPwm.duty_u16() / 65536) * 100))

print('PWM width (ns) =', motorPwm.duty_ns())

return

# *** Motor Test Functions ***

def testMoveMotor01(motorDriverDictNum, motorNum):

# *** Setup Driver ***

setupMotorDriver(motorDriverDictNum)

# *** Move motor forward ***

moveMotorForward(motorDriverDictNum, motorNum)

utime.sleep(1)

# *** Move motor backward ***

moveMotorBackward(motorDriverDictNum, motorNum)

utime.sleep(1)

# *** Move motor stop ***

moveMotorStop(motorDriverDictNum, motorNum)

return

def testMeasureMotorSpeed01(motorDriverDictNum, motorNum):

measureMotorSpeed(motorDriverDictNum, motorNum)

return

def testSetupMotorPwm01(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

setupPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

return

# *** Main Tests ***

# *** Test move motor forward, backward, stop ***

# print('Test Motor #1 Move Forward, Backward, Stop')

# testMoveMotor01(motorDriverDictNum = 1, motorNum = 1)

# print('Test Motor #2 Move Forward, Backward, Stop')

# testMoveMotor01(motorDriverDictNum = 1, motorNum = 2)

# *** Test measure motor speed ***

# print('\nTest Measure Motor #1 Speed')

#testMeasureMotorSpeed01(motorDriverDictNum = 1, motorNum = 1)

# *** Test PWM Funcions ***

print('\nTest PWM Funcions')

testSetupMotorPwm01(motorDriverDictNum = 1, motorNum =1, pwmFreq = 1000, dutyCycle = 50)

# *** End of program ***

# *** Sample Output - tlfong01 2021aug18hkt1120

'''

>>> %Run -c $EDITOR_CONTENT

revUs = 1250

rps = 800

rpm raw = 48000

rpm 100 = 480

>>>

'''

'''

>>> %Run -c $EDITOR_CONTENT

Test PWM Funcions

PWM freq (Hz) = 1000

PWM duty (%) = 49

PWM width (ns) = 499728

>>>

'''

I have modified my old program to use PWM pin to control the speed of the motor (earlier I only used PWM pin as high/low logical signal to turn motor fully on or off. Now I am using PWM 1kHz and duty cycle 0~100% to control speed of motor. I found, as expected, motor moves slowly with duty cycle small and quickly with high duty cycle. However, I found the speed measurement function not reliable, mainly because I use counting 100 logical low level signals/revolutions from encoder, and I did not set the between low levels appropriately. Now I am thinking of using interrupt to detect number of high to low falling edges in a specified time period to calculate the motor speed. This way the measurement of speed should be more accurate.

Anyway, I am listing my old speed measurement program to do interrupt driven method to compare and contrast.

Note - I found that this long post exceeds the forum’s 32k words limit. So I am deleting some functions to fit the bill.

# Program Name

# measure_motor_speed_v16.py - tlfong01 2021aug19hkt1132

# docs and functions deleted

import utime

from machine import Pin, PWM

# *** Configuration ***

motorDriverDict01 = {

'TITLE' : 'TB6612FNG Dual DC Motor Driver Dictionary',

'STANDBY' : 5,

'1': {'IN1': 10, 'IN2': 11, 'PWM' : 3, 'ENCODE': 14},

'2': {'IN1': 12, 'IN2': 13, 'PWM' : 4, 'ENCODE': 15},

'3': {'IN1': 0, 'IN2': 0, 'PWM' : 0, 'ENCODE': 0},

'4': {'IN1': 0, 'IN2': 0, 'PWM' : 0, 'ENCODE': 0},

}

motorDriverDictDict = {

'1': motorDriverDict01,

'2': motorDriverDict01,

}

# *** Read Motor Encoder, Measure Motor Speed ***

def readMotorEncodeValue(motorDriverDictNum, motorNum):

motorControlPinList = setupMotor(motorDriverDictNum, motorNum)

encodeValue = motorControlPinList[3].value()

return encodeValue

def measureMotorSpeed(motorDriverDictNum, motorNum):

# *** Setup Motor Driver ***

setupMotorDriver(motorDriverDictNum)

# *** Move motor forward ***

moveMotorForward(motorDriverDictNum, motorNum)

# *** Measure Motor Speed ***

# *** Start counting 10 revolutions ***

usTicks1 = utime.ticks_us()

# *** Find lapse time of 100 revolutions ***

revCount = 0

while revCount < 10:

if readMotorEncodeValue(motorDriverDictNum, motorNum) == 0:

revCount = revCount + 1

utime.sleep(0.000001)

usTicks2 = utime.ticks_us()

rev10Us = utime.ticks_diff(usTicks2, usTicks1)

revUs = int(rev10Us / 10)

rps = int(1000000 / revUs)

rpmRaw = int(rps * 60)

rpmGear100 = int(rpmRaw / 100)

print(' uS per revolution =', revUs)

print(' rps raw =', rps)

print(' rpm raw =', rpmRaw)

print(' rpm gear 1:100 =', rpmGear100)

return rpmGear100

# *** PWM Functions ***

def setupMotorDriverPwm(motorDriverDictNum):

motorDriverDict = motorDriverDictDict[str(motorDriverDictNum)]

# print(' motDriverDictNum =', motorDriverDictNum)

standBy = Pin(motorDriverDict['STANDBY'], Pin.OUT)

standBy.high()

return

def setupMotorPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

motorDriverDict = motorDriverDictDict[str(motorDriverDictNum)]

motorIn1Pin = motorDriverDict[str(motorNum)]['IN1']

motorIn2Pin = motorDriverDict[str(motorNum)]['IN2']

motorPwmPin = motorDriverDict[str(motorNum)]['PWM']

# print(' IN1 pinNum =', motorIn1Pin)

# print(' IN2 pinNum =', motorIn2Pin)

# print(' PWM pinNum =', motorPwmPin)

motorIn1 = Pin(motorIn1Pin, Pin.OUT)

motorIn2 = Pin(motorIn2Pin, Pin.OUT)

motorPwm = PWM(Pin(motorDriverDict[str(motorNum)]['PWM']))

motorPwm.freq(pwmFreq)

motorPwm.duty_u16(int(65536 / 100) * dutyCycle)

pwmPinNum = motorDriverDict[str(motorNum)]['PWM']

# print(' Setup PWM')

# print(' PWM freq (Hz) =', motorPwm.freq())

# print(' PWM duty (%) =', int((motorPwm.duty_u16() / 65536) * 100))

# print(' PWM width (ns) =', motorPwm.duty_ns())

motorEncode = Pin(motorDriverDict[str(motorNum)]['ENCODE'], Pin.IN, Pin.PULL_DOWN)

motorControlPinList = [motorIn1, motorIn2, motorPwm, motorEncode]

return motorControlPinList

def moveMotorForwardPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

motorControlPinList = setupMotorPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

motorControlPinList[0].low()

motorControlPinList[1].high()

motorControlPinList[2].freq(pwmFreq)

motorControlPinList[2].duty_u16(int(65536 / 100) * dutyCycle)

return

def measureMotorSpeedPwm(motorDriverDictNum, motorNum):

# *** Setup Motor Driver ***

# setupMotorDriver(motorDriverDictNum)

# *** Move motor forward ***

# moveMotorForwardPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

# *** Measure Motor Speed ***

# *** Start counting 10 revolutions ***

usTicks1 = utime.ticks_us()

# *** Find lapse time of 100 revolutions ***

revCount = 0

while revCount < 10:

if readMotorEncodeValue(motorDriverDictNum, motorNum) == 0:

revCount = revCount + 1

utime.sleep(0.0001) # <<<<<<<<<<<<

usTicks2 = utime.ticks_us()

rev10Us = utime.ticks_diff(usTicks2, usTicks1)

revUs = int(rev10Us / 10)

rps = int(1000000 / revUs)

rpmRaw = int(rps * 60)

rpmGear100 = int(rpmRaw / 100)

# print(' uS per revolution =', revUs)

# print(' rps raw =', rps)

# print(' rpm raw =', rpmRaw)

# print(' rpm gear 1:100 =', rpmGear100)

return rpmGear100

# *** Motor Test Functions ***

def testMoveMotor01(motorDriverDictNum, motorNum):

# *** Setup Driver ***

setupMotorDriver(motorDriverDictNum)

# *** Move motor forward ***

moveMotorForward(motorDriverDictNum, motorNum)

utime.sleep(1)

# *** Move motor backward ***

moveMotorBackward(motorDriverDictNum, motorNum)

utime.sleep(1)

# *** Move motor stop ***

moveMotorStop(motorDriverDictNum, motorNum)

return

def testMeasureMotorSpeed01(motorDriverDictNum, motorNum):

measureMotorSpeed(motorDriverDictNum, motorNum)

return

#def testSetupMotorPwm01(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

# setupPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

# return

def testMoveMotorForwardPwm01(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

setupMotorDriverPwm(motorDriverDictNum)

moveMotorForwardPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

utime.sleep(4)

moveMotorStop(motorDriverDictNum, motorNum)

return

def testMeasureMotorSpeedPwm01(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

setupMotorDriverPwm(motorDriverDictNum)

moveMotorForwardPwm(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

utime.sleep(2)

speedRpmGear = measureMotorSpeedPwm(motorDriverDictNum, motorNum)

print('dutyCycle =', dutyCycle)

print('speed (rpmGear) =', speedRpmGear)

# moveMotorStop(motorDriverDictNum, motorNum)

return

# *** Main Tests ***

# *** Test move motor forward, backward, stop ***

# print('Test Motor #1 Move Forward, Backward, Stop')

# testMoveMotor01(motorDriverDictNum = 1, motorNum = 1)

# print('\nTest Motor #2 Move Forward, Backward, Stop')

# testMoveMotor01(motorDriverDictNum = 1, motorNum = 2)

# *** Test measure motor speed ***

# print('\nTest Measure Motor #1 Speed')

# testMeasureMotorSpeed01(motorDriverDictNum = 1, motorNum = 1)

# *** Test Move Motor / Measure Speed PWM Funcions ***

print('Test Move Motor Forward')

# testMoveMotorForwardPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 100)

# testMoveMotorForwardPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 50)

# testMoveMotorForwardPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 10)

print('Test Measure Motor Speed')

testMeasureMotorSpeedPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 80)

print('Test Measure Motor Speed')

testMeasureMotorSpeedPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 50)

print('Test Measure Motor Speed')

testMeasureMotorSpeedPwm01(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 40)

print('Stop Motor')

moveMotorStop(motorDriverDictNum = 1, motorNum = 1)

# *** End of program ***

# *** Sample Output - tlfong01 2021aug18hkt1120

'''

MicroPython v1.16 on 2021-06-18; Raspberry Pi Pico with RP2040

Type "help()" for more information.

>>> %Run -c $EDITOR_CONTENT

Test Move Motor Forward

Test Measure Motor Speed

dutyCycle = 80

speed (rpmGear) = 479

Test Measure Motor Speed

dutyCycle = 50

speed (rpmGear) = 479

Test Measure Motor Speed

dutyCycle = 40

speed (rpmGear) = 524

Stop Motor

>>>

'''

'''

>>> %Run -c $EDITOR_CONTENT

Test PWM Funcions

PWM freq (Hz) = 1000

PWM duty (%) = 49

PWM width (ns) = 499728

>>>

'''

Note - This reply post is getting too long, exceeding the forum’s 32k word limit. So I am breaking up to another reply.

/ to continue, …

This reply follows from the early long reply. I am starting to study how to use microPython interrupt, to write a new function to measure the speed of the N20 geared motor with encoders.

Interrupt Learning Notes

I know interrupt handlers (Interrupt Service Routines, ISR’s) are very difficult to debug. So my goal is try to write an interrupt handler as simple as possible, but not simpler.

Below are the tutorials I will start reading, before writing the very simple interrupt handler for measuring the speed of the N20 motor.

(1) Raspberry Pi GPIO Interrupts Tutorial

(2) MicroPython Writing interrupt handlers

(3) Dual Cores & Interrupts on Pi Pico (Using Thonny) - By tonygo2

MicroPython Writing interrupt handlers - Reading Notes

Tips and recommended practices

…

Where an ISR returns multiple bytes use a pre-allocated bytearray. If multiple integers are to be shared between an ISR and the main program consider an array (array.array).

Where data is shared between the main program and an ISR, consider disabling interrupts prior to accessing the data in the main program and re-enabling them immediately afterwards (see Critical Sections).

Simplicity

For a variety of reasons it is important to keep ISR code as short and simple as possible. It should do only what has to be done immediately after the event which caused it: operations which can be deferred should be delegated to the main program loop. Typically an ISR will deal with the hardware device which caused the interrupt, making it ready for the next interrupt to occur. It will communicate with the main loop by updating shared data to indicate that the interrupt has occurred, and it will return. An ISR should return control to the main loop as quickly as possible.

Communication between an ISR and the main program

Normally an ISR needs to communicate with the main program. The simplest means of doing this is via one or more shared data objects, either declared as global or shared via a class (see below). There are various restrictions and hazards around doing this, which are covered in more detail below. Integers, bytes and bytearray objects are commonly used for this purpose along with arrays (from the array module) which can store various data types.

Creation of Python objects

One way to avoid this issue is for the ISR to use pre-allocated buffers. For example a class constructor creates a bytearray instance and a boolean flag. The ISR method assigns data to locations in the buffer and sets the flag. The memory allocation occurs in the main program code when the object is instantiated rather than in the ISR.

N20 Motor Speed Measurement Function Using 2 Core Pico and Interrupts - Part 1

I skimmed all three tutorials above and found Ref 1 good as a general introduction to interrupts. But it is based on Rpi4, not on Pico, so not too useful else. Ref 2 is base on MicroPython, but a bit too advanced for newbies. Ref 3 by TonyGo2 is very good, very newbie friend and can be used as a template to adapt to my motor speed measurement function. It uses 2 core Pico and also Thonny MicroPython. So I am thinking a learning 2 core programming using this example.

Last reply exceeded the forum’s 32k words limit. So this time I am using the Penzu stuff to make this reply’s program listing shorter, as show below.

Motor Speed Measure v0.1 Program Listing

I found the TonyGo2 tutorial on interrupt handler good, but not easy to adapt to my simple applications. So I searched for more newbie friendly tutorials and found the first two of the following three tutorials good.

(2) How to use the two Cores of the Pi Pico? And how fast are Interrupts? - Andreas Spiess, 71,479 views, 2021feb21 (Two thread/core at 5:03, Interrupt at 8:04, frequency ounter at 8:54, PIO fast counter at 11:04)

(3) Rpi Pico hardware_irq Hardware APIs - SDK Documentation

The first tutorial from RoboCraze is simple, so I will be using it to adapt to my N20 motor speed measurement. Andreas Spiess’s tutorial is very comprehensive. So I might use it to improve my first trial of speed measurement.

Now I am looking closely at RoboCraze’s interrupt program example, which I think is excellent for newbies, because it is what I used to say “Make it as simple as possible, but not simpler” or often called the Ockham’s Razor. RoboCraze’s example is good in that it does not even use any global variable/flag/counter. The main part is shown below:

Now I have debugged a preliminary version of the N20 speed measurement function spv30310.py.

This version does the following:

1. Setup and move motor forward

2. Setup and move motor backward

3. Setup and measure motor speed

# Program Name

# spv31313_2021aug2101.py - tlfong01 2021aug21hkt2058

# Reference

# Pi-Top Forum - making-a-rpi-pico-based-smart-vehicle/924

# https://forum.pi-top.com/t/making-a-rpi-pico-based-smart-vehicle/924

#

# Configuration

# Acer Aspire Intel COIRE i5 PC Chinese Windows 10 (64-bit), Thonny 3.3.3, Python 3.7.9 (32-bit), Tk 8.6.9, USB COM Port #4

#

# Thonny MicroPython Intepreter

# Micropython (Rapsberry Pi Pico)

#

# DC Motor

# N20 1:100 6V DC Gear Motor with quadrature encoder signals A, B

# N20 Gear Motor Spec (6V gear 1:100 no load speed = 300 rpm (https://www.pololu.com/search/compare/173)

#

# DC Motor Driver

# TB6612FNG Dual DC Motor Driver

# Brief Description of Program Function

# 1. Move DC motor N20 forward, backware, stop.

# 2. Use PWM to control motor speed

# 3. Use N20 motor encoder to measure speed

# ========= ========= ========= ========= ========= ========= ========= ========= ========= =========

# ========= ========= ========= ========= ========= ========= ========= ========= ========= =========

# ========= ========= ========= ========= ========= ========= ========= ========= ========= =========

# ========= ========= ========= ========= ========= ========= ========= ========= ========= =========

import utime

from machine import Pin, PWM

# *** Configuration ***

motorDriverDict01 = {

'TITLE' : 'TB6612FNG Dual DC Motor Driver Dictionary v0.1 tlfong01 2021aug21hkt0949',

'STANDBY' : 5,

'1': {'IN1': 10, 'IN2': 11, 'PWM' : 3, 'ENCODE': 14},

'2': {'IN1': 12, 'IN2': 13, 'PWM' : 4, 'ENCODE': 15},

'3': {'IN1': 0, 'IN2': 0, 'PWM' : 0, 'ENCODE': 0},

'4': {'IN1': 0, 'IN2': 0, 'PWM' : 0, 'ENCODE': 0},

}

motorDriverDictDict = {

'1': motorDriverDict01,

'2': motorDriverDict01,

}

# *** Motor Functions ***

def setupMotor(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

motorDriverDict = motorDriverDictDict[str(motorDriverDictNum)] # Get driver dict

driverStandBy = Pin(motorDriverDict['STANDBY'], Pin.OUT) # create driverStandBy pin object

motorIn1 = Pin(motorDriverDict[str(motorNum)]['IN1'], Pin.OUT) # Create Motor # motorNum In1 pin object

motorIn2 = Pin(motorDriverDict[str(motorNum)]['IN2'], Pin.OUT) # Create Motor # motorNum In2 pin object

motorPwm = PWM(Pin(motorDriverDict[str(motorNum)]['PWM'])) # Create Motor # motorNum Pwm pin object

motorEncode = Pin(motorDriverDict[str(motorNum)]['ENCODE'], Pin.IN, Pin.PULL_DOWN) # Create Motor # motorNum Encode pin object

motorConfigDict = {'StdBy': driverStandBy, 'In1': motorIn1, 'In2': motorIn2, 'Pwm': motorPwm, 'Encode': motorEncode, \

'PwmFreq': pwmFreq, 'DutyCycle': dutyCycle}

motorConfigDict['StdBy'].high() # enable motor driver normal operation, (low = disable)

motorConfigDict['Pwm'].freq(pwmFreq) # setup frequency

motorConfigDict['Pwm'].duty_u16(int(65536 / 100) * dutyCycle) # and duty cycle

stopMotor(motorConfigDict)

return motorConfigDict

def moveMotorForwardNonStop(motorConfigDict):

motorConfigDict['In1'].low() # move motor

motorConfigDict['In2'].high() # backward

return

def stopMotor(motorConfigDict):

motorConfigDict['In1'].low()

motorConfigDict['In2'].low()

return

def moveMotorForward(motorConfigDict, moveSeconds):

motorConfigDict['In1'].low()

motorConfigDict['In2'].high()

utime.sleep(moveSeconds)

stopMotor(motorConfigDict)

return

def moveMotorBackward(motorConfigDict, moveSeconds):

motorConfigDict['In1'].high()

motorConfigDict['In2'].low()

utime.sleep(moveSeconds)

stopMotor(motorConfigDict)

return

# *** Test Functions ***

def testMoveMotorForward(motorDriverDictNum, motorNum, pwmFreq, dutyCycle, moveSeconds):

print('\ntestMoveMotorForward()')

motorConfigDict = setupMotor(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

moveMotorForward(motorConfigDict, moveSeconds)

stopMotor(motorConfigDict)

return

def testMoveMotorBackward(motorDriverDictNum, motorNum, pwmFreq, dutyCycle, moveSeconds):

print('\ntestMoveMotorBackward()')

motorConfigDict = setupMotor(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

moveMotorBackward(motorConfigDict, moveSeconds)

stopMotor(motorConfigDict)

return

def testMeasureMotorSpeed(motorDriverDictNum, motorNum, pwmFreq, dutyCycle):

print('\ntestMeasureMotorSpeed(), ...')

# *** Setup motor and move motor forward ***

motorConfigDict = setupMotor(motorDriverDictNum, motorNum, pwmFreq, dutyCycle)

moveMotorForwardNonStop(motorConfigDict)

# *** Define callback funtion ***

def encodeIntCallBack(pin):

global encodeIntEventCount

encodeIntEventCount = encodeIntEventCount + 1

return

# *** Setup callback function ***

motorConfigDict['Encode'].irq(encodeIntCallBack, Pin.IRQ_FALLING)

# *** Count Encode Interrupt Events Every Second ***

global encodeIntEventCount

encodeIntEventCount = 0

totalSecondCount = 4

#print('totalSecondCount =', totalSecondCount)

for secondCount in range(totalSecondCount):

#print('TotalEncodeIntEventCount =', encodeIntEventCount)

utime.sleep(1)

avgEncodeIntEventCount = int(encodeIntEventCount / totalSecondCount)

#print('pwmFreq =', motorConfigDict['PwmFreq'])

print('dutyCycle =', motorConfigDict['DutyCycle'])

#print('average encodeIntEventCount Per Second =', avgEncodeIntEventCount)

print('N20 rpm =', int((avgEncodeIntEventCount * 60)/100))

return

# *** Main ***

testMoveMotorForward(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 90, moveSeconds = 1)

testMoveMotorBackward(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 90, moveSeconds = 1)

testMeasureMotorSpeed(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 100)

testMeasureMotorSpeed(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 50)

testMeasureMotorSpeed(motorDriverDictNum = 1, motorNum = 1, pwmFreq = 1000, dutyCycle = 10)

# End

'''

Sample output - tlfong01 2021aug21

>>> %Run -c $EDITOR_CONTENT

testMoveMotorForward()

testMoveMotorBackward()

testMeasureMotorSpeed(), ...

dutyCycle = 100

N20 rpm = 960

testMeasureMotorSpeed(), ...

dutyCycle = 50

N20 rpm = 454

testMeasureMotorSpeed(), ...

dutyCycle = 10

N20 rpm = 52

>>>

'''

Now I am plotting N20 motor rpm speed vs dutyCycle using the following speed measurement results

testMeasureMotorSpeed(), …

dutyCycle = 100

N20 rpm = 964

testMeasureMotorSpeed(), …

dutyCycle = 955

N20 rpm = 67

testMeasureMotorSpeed(), …

dutyCycle = 90

N20 rpm = 868

testMeasureMotorSpeed(), …

dutyCycle = 80

N20 rpm = 769

testMeasureMotorSpeed(), …

dutyCycle = 70

N20 rpm = 661

testMeasureMotorSpeed(), …

dutyCycle = 60

N20 rpm = 553

testMeasureMotorSpeed(), …

dutyCycle = 50

N20 rpm = 448

testMeasureMotorSpeed(), …

dutyCycle = 40

N20 rpm = 351

testMeasureMotorSpeed(), …

dutyCycle = 30

N20 rpm = 247

testMeasureMotorSpeed(), …

dutyCycle = 20

N20 rpm = 150

testMeasureMotorSpeed(), …

dutyCycle = 10

N20 rpm = 50

testMeasureMotorSpeed(), …

dutyCycle = 5

N20 rpm = 0

I am glad to see that the N20 motor rpm speed vs pwm duty cycle is very linear.

Motor to motor speed difference

I tested two motors and found the following difference.

motorNum = 1 dutyCycle = 50 N20 rpm = 445

motorNum = 2 dutyCycle = 50 N20 rpm = 473

The speed difference is about 473 / 445 ~=6%

This means that if both motors are moved with duty cycle 50%, the wheel speed is about 6%, or in other words the vehicle will not move in a straight line.

So if I want the vehicle move in a straight line, I need to adjust the duty cycle of each motor.

Distance traveled vs motor moving time

Now I am modifying the program to find the distance of a 6.3cm diameter wheel traveled in 4 seconds.

Sample Output (my dodgy calculation not verified! :))

>>> %Run -c $EDITOR_CONTENT

motorNum = 1 dutyCycle = 50 seconds moved = 4

revolution made = 2883

1/100 geared wheel revolutions made = 28

distance traveled (cm) = 570

>>>

Errata - I forgot that the quadrature encoder might have 6, 12 or more pulses/counts per revolution. So the actual distance traveled in the above calculation should be 570 / 12 ~= 50cm.

Note - But I am not too sure. I am using only the falling edge of only Signal A of the quadrature encoder. Some specs says Count Per Revolution (CPR) is 4 times of Pulses Per Revolution (PPR), because CPR takes care of both Signals A, and B, and both falling and rising edges.

How to move a specified distance

So I moved on to write a function to move to a specified distance, say 1 metre. I timed the time required to move one revolution and calculate the specified distance by the distance of one revolution, and get the number of revolution required distance. However, I found this trick does not work, because the time for the first or second revolution is longer that the later revolutions (because it take time to start moving motor and more time to settle down to a steady speed). So I think a better way is to calculate the number of encode interrupts for one revolution, instead of the time required for one revolution. This distance vs encode interrupt counts is also good, because it is independent of speed, PWM frequency, and duty cycle magnitude.

Anyway, the program for using the wrong trick is listed below.

Bad program for moving to a specified distance

Number of Encode Interrupt Counts Per Revolution

I found that for pwmFreq = 1000, dutyCycle = 50, time required to move motor for one revolution is about 1.38 seconds, and

the more precise number of interrupt counts for one revolution is 983, which is a very important number for my later programs.

Refactoring

spv31325.py can now move a number of encode interrupts/revolutions/distance

Considering trying two core interrupts

Now that my motor moving program using interrupts is working properly, I am thinking of try out two core interrupt as described in the TonyGo2 tutorial. I found the trick is simple, but makes the processing more complicated. So I am not try it for now. Anyway, I summarized TonyGo2’s programming below, for later reference.

TonyGo2' Tutorial (https://www.instructables.com/Dual-Cores-Interrupts-on-Pi-Pico/)

1. Break down into 3 parts.

a. Setting up and activating the cores

b. Shutting down the cores in sequence

c. Using interrupts

2. Two Core/Process/Thread operation

a. Core 0 process/thread counts (button pushing) interrupts and does something when counts up (to 30)

b. Core 1 process/thread blinks LEDs

3. Programming

a. Imports _thread module

b. Imports gc (garbage module)

c. Two Core 0 process/tasks

Two interrupt pins associated with two interrupt events (and Interrupt Service Routines (IsRS):

(i) "LedDirectionTask(pin)" triggered by "Led direction pin signal rising edge"

(ii) "HaltTask(pin), triggered by "Halt pin signal rising edge"

d. One Core 1 process/task

(i) main process running LEDs, thread exits if not "running".

(ii) garbage collect if interrupt counts to 100

Testing two motors

How to drive the 2WD (1) in a straight line, (b) in a circle, © in a square

Now that I know how to count Encoder signals in a time period, it is time to do more fancy things, like driving the 2WD in a straight line. Before that, I need to ‘sync’ the two motor’s encoder interrupt count, distance traveled etc. A sample output of the calibration is shown below:

'''

Sample output - tlfong01 2021aug25hkt1145

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 100 MoveSeconds =, 1 encodeIntCount = 1563

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 100 MoveSeconds =, 1 encodeIntCount = 1941

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 50 MoveSeconds =, 1 encodeIntCount = 1077

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 50 MoveSeconds =, 1 encodeIntCount = 830

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 10 MoveSeconds =, 1 encodeIntCount = 193

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 10 MoveSeconds =, 1 encodeIntCount = 88

>>>

'''

And the program listed below:

Realtime Sync Design Notes

I found the sync by interrupt count not very reliable on order of seconds, as summarized below.

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 1 encodeIntCount = 809

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 1 encodeIntCount = 808

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 1 encodeIntCount = 810

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 1 encodeIntCount = 824

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 1 encodeIntCount = 808

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 1 encodeIntCount = 814

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 1 encodeIntCount = 809

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 1 encodeIntCount = 820

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 10 encodeIntCount = 8390

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 10 encodeIntCount = 7388

>>> %Run -c $EDITOR_CONTENT

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 55 MoveSeconds =, 100 encodeIntCount = 84405

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 48 MoveSeconds =, 100 encodeIntCount = 72700

>>>

The root problem is that the differential speed error accumulates, with the result that it is not practical to use this trick the drive the vehicle move in a straight line, not to mention in a circle or a square. So I now need to do realtime sync, not in seconds resolution, but in milliseconds. The idea is to watch speed/distance millisecond by millisecond and adjust one or both duty cycles to minimize the difference.

This reply is getting too long and confusing. So I am making a new reply with a selfie walk through of what I have bee doing, and finally reached this point as a milestone. The following version of program is working version of all the testing functions at the motor level. Next reply will move up to the 2WD vehicle’s wheel level. In Object Oriented Programming sense, the new classes at wheel level is higher than the motor level. In Functional Programming sense, the MicroPython dictionaries at moving from motor to wheels/vehicle level.

SPV v4.0 Program

/ to continue, …

SPV(Smart Pico Vehicle)v4.0 - Introduction

This is reply to the last 13 or so replies of this smart vehicle project. I know that using the term “reply” is a bit confusing. Actually I am, in effect, writing a “blog” of the project. I think the term “blog” better reflects the situation, that it is like a diary, with dates of my project progress, especially the mistakes I have been making, which is revealed when doing the tests to verify my project design and direction is more or less OK. I need to remind myself that I am doing TDD (Test Driven Development), or PBL (Problem Based Learning), or Agile/Prototyping, or a mix of all the three approaches. The other thing I need to remind myself is that I am doing sort of structured programming, distributed processing, multiprocessing/multithreading, functional programming (but not object oriented programming).

Now I will do a brief selfie walk through, or an intermittent progress report, in the form of casual, random notes.

I started with Rpi Pico MCU, and N20 geared motor with quadrature encoder, because I read other users proposed these two things.

I got my Pico’s some months ago, but have been a bit lazy to try it out. I did read about Tom’s Hardware tutorials, and other interesting YouTube videos (especially those by the funny Swiss guy) which I think is good for newbies to start off.

I have been using popular DC motor drivers such as L298N to drive two motor vehicles, but only at the start off stage, controlling by PWM by Rpi3/4. I remember one motor driver tutorial challenged to do more advanced things such as moving the two wheeled car/robot in a square. I noticed that no newbies reported that they did it. So I think there is a steep learning curve on how to teach the 2WD to do smart things, like move in a straight line, in a circle, in a square etc.

It was only when I tried out different things, like motor encoder signal interrupts, especially with 2 core Pico, that the stuff is very tricky, especially for newbies. That is why that I need to look back the over ambitious goals I hope to reach, and mistakes I made, before I move on my smart vehicle project.

Now let me report what I am getting stuck at this point. I found moving the N20 motor with a simple spec or requirement such as (1) number of revolutions, (2) number of motor encoder signals/pulses, (3) distance, eg, 1 or 2 meters, is difficult, if precision is needed (eg 5% accuracy/resolution), not to mention synchronizing two or four motors.

So now I am going back a bit and redo some of the tests and calibrations, as a preparation of doing this seemingly easy thing:

Moving a 2WD in a straight line

First thing I need to do is to calibrate the N20 motor encoder interrupt signal timing. I am using the following scope to display the waveforms.

Digital Oscilloscope ATTEN ADS1102CAL+

ATTEN ADS100 User Manual

Now I am using my 100MHz DSO to display the N20 motor encoders pulse signal waveform. I found that for PWM frequency 1kHz, Duty cycle 50%, both motor’s encoders give about 700 pulses per second. I will be using this number 770Hz as calibration/bench mark for my future tests.

And the time has come to try to move my 2WD in a straight line, before trying out the more advanced tricks of Pi Top [4] DIY 2WD, such as autonomous driving in a straight line.

Discrepancy between python program measurement and scope display

I lookded back what I measured earlier using python program, with the following results:

MotorDriverDictNum = 2 MotorNum = 1 PWM Freq = 1000 DutyCycle = 50 MoveSeconds =, 1 encodeIntCount = 1077

MotorDriverDictNum = 2 MotorNum = 2 PWM Freq = 1000 DutyCycle = 50 MoveSeconds =, 1 encodeIntCount = 830

It is weird that software results 1077 and 830 interrupt counts per second, but scope measure around 760~770 interrupt counts per second. I need to find out why software counts more interrupts hardware scope. If software results are not reliable or inaccurate, then it would be difficult o sync two motors/wheels to move vehicle in a straight. Perhaps I need to use more motor samples to find out the cause of discrepancy.

PiTop [4] and PiPico Gesture Control

I remember PiTop [4] is using MPU6050 to do smart things like gesture control. So I am hoping to use the same or similar gyro and accelero for fun. This morning I read a newbie friendly tutorial on using MPU6050. So I will try it later.

Using Gyroscope and accelerometer with MPU6050, Rpi Pico and MicroPython - Peppr80, 2021aug85

Pi-Top Encoder Motor API

Now I am read the Pi-Top Encoder API, to see what classes, functions, and parameters are used in their library. There are parameters I understand, such as wheel diameter and circumference. But are some I don’t understand exactly what they are, for example, two types of stopping the motor.

Pi-Top Encoder Motor API - Pi-Top

6. API - pi-top Maker Architecture (PMA) Components

6.3. Encoder Motor

Note

This is a Motor Component which connects to a MotorEncoder Port [M0-M3].

from pitop import (

EncoderMotor,

ForwardDirection,

BrakingType

)

from time import sleep

# Setup the motor

motor = EncoderMotor("M0", ForwardDirection.COUNTER_CLOCKWISE)

motor.braking_type = BrakingType.COAST

# Move in both directions

rpm_speed = 100

for _ in range(4):

motor.set_target_rpm(rpm_speed)

sleep(2)

motor.set_target_rpm(-rpm_speed)

sleep(2)

motor.stop()

classpitop.pma.EncoderMotor(port_name, forward_direction, braking_type=<BrakingType.COAST: 0>, wheel_diameter=0.075, name=None)[source]

Represents a pi-top motor encoder component.

Note that pi-top motor encoders use a built-in closed-loop control system, that feeds the readings from an encoder sensor to an PID controller. This controller will actively modify the motor’s current to move at the desired speed or position, even if a load is applied to the shaft.

This internal controller is used when moving the motor through set_target_rpm or set_target_speed methods, while using the set_power method will make the motor work in open-loop, not using the controller.

Note

Note that some methods allow to use distance and speed settings in meters and meters per second. These will only make sense when using a wheel attached to the shaft of the motor.

The conversions between angle, rotations and RPM used by the motor to meters and meters/second are performed considering the wheel_diameter parameter. This parameter defaults to the diameter of the wheel included with MMK. If a wheel of different dimmensions is attached to the motor, you’ll need to measure it’s diameter, in order for these methods to work properly.

Parameters:

port_name (str) – The ID for the port to which this component is connected.

forward_direction (ForwardDirection) – The type of rotation of the motor shaft that corresponds to forward motion.

braking_type (BrakingType) – The braking type of the motor. Defaults to coast.

wheel_diameter (int or float) – The diameter of the wheel attached to the motor.

backward(target_speed, distance=0.0)[source]

Run the wheel backwards at the desired speed in meters per second.

This method is a simple interface to move the wheel that wraps a call to set_target_speed, specifying the back direction.

If desired, a distance to travel can also be specified in meters, after which the motor will stop. Setting distance to 0 will set the motor to run indefinitely until stopped.

Note

Note that for this method to move the wheel the expected distance, the correct wheel_circumference value needs to be used.

Parameters:

target_speed (int or float) – Desired speed in m/s

distance (int or float) – Total distance to travel in m. Set to 0 to run indefinitely.

braking_type

Returns the type of braking used by the motor when it’s stopping after a movement.

Setting this property will change the way the motor stops a movement:

BrakingType.COAST will make the motor coast to a halt when stopped.

BrakingType.BRAKE will cause the motor to actively brake when stopped.

Parameters: braking_type (BrakingType) – The braking type of the motor.

current_rpm

Returns the actual RPM currently being achieved at the output shaft, measured by the encoder sensor.

This value might differ from the target RPM set through set_target_rpm.

current_speed

Returns the speed currently being achieved by the motor in meters per second.

This value may differ from the target speed set through set_target_speed.

distance

Returns the distance the wheel has travelled in meters.

This value depends on the correct wheel_circumference value being set.

forward(target_speed, distance=0.0)[source]

Run the wheel forward at the desired speed in meters per second.

This method is a simple interface to move the motor that wraps a call to set_target_speed, specifying the forward direction.

If desired, a distance to travel can also be specified in meters, after which the motor will stop. Setting distance to 0 will set the motor to run indefinitely until stopped.

Note

Note that for this method to move the wheel the expected distance, the correct wheel_circumference value needs to be used.

Parameters:

target_speed (int or float) – Desired speed in m/s

distance (int or float) – Total distance to travel in m. Set to 0 to run indefinitely.

forward_direction

Represents the forward direction setting used by the motor.

Setting this property will determine on which direction the motor will turn whenever a movement in a particular direction is requested.

Parameters: forward_direction (ForwardDirection) – The direction that corresponds to forward motion.

max_rpm

Returns the approximate maximum RPM capable given the motor and gear ratio.

max_speed

The approximate maximum speed possible for the wheel attached to the motor shaft, given the motor specs, gear ratio and wheel circumference.

This value depends on the correct wheel_circumference value being set.

own_state

Representation of an object state that will be used to determine the current state of an object.

power()[source]

Get the current power of the motor.

Returns a value from -1.0 to +1.0, assuming the user is controlling the motor using the set_power method (motor is in control mode 0). If this is not the case, returns None.

rotation_counter

Returns the total or partial number of rotations performed by the motor shaft.

Rotations will increment when moving forward, and decrement when moving backward. This value is a float with many decimal points of accuracy, so can be used to monitor even very small turns of the output shaft.

set_power(power, direction=<Direction.FORWARD: 1>)[source]

Turn the motor on at the power level provided, in the range -1.0 to +1.0, where:

1.0: motor will turn with full power in the direction provided as argument.

0.0: motor will not move.

-1.0: motor will turn with full power in the direction contrary to direction.

Warning

Setting a power value out of range will cause the method to raise an exception.

Parameters:

power (int or float) – Motor power, in the range -1.0 to +1.0

direction (Direction) – Direction to rotate the motor

set_target_rpm(target_rpm, direction=<Direction.FORWARD: 1>, total_rotations=0.0)[source]

Run the motor at the specified target_rpm RPM.

If desired, a number of full or partial rotations can also be set through the total_rotations parameter. Once reached, the motor will stop. Setting total_rotations to 0 will set the motor to run indefinitely until stopped.

If the desired RPM setting cannot be achieved, torque_limited will be set to True and the motor will run at the maximum possible RPM it is capable of for the instantaneous torque. This means that if the torque lowers, then the RPM will continue to rise until it meets the desired level.

Care needs to be taken here if you want to drive a vehicle forward in a straight line, as the motors are not guaranteed to spin at the same rate if they are torque-limited.

Warning

Setting a target_rpm higher than the maximum allowed will cause the method to throw an exception. To determine what the maximum possible target RPM for the motor is, use the max_rpm method.

Parameters:

target_rpm (int or float) – Desired RPM of output shaft

direction (Direction) – Direction to rotate the motor. Defaults to forward.

total_rotations (int or float) – Total number of rotations to be execute. Set to 0 to run indefinitely.

set_target_speed(target_speed, direction=<Direction.FORWARD: 1>, distance=0.0)[source]

Run the wheel at the specified target speed in meters per second.

If desired, a distance to travel can also be specified in meters, after which the motor will stop. Setting distance to 0 will set the motor to run indefinitely until stopped.

Warning

Setting a target_speed higher than the maximum allowed will cause the method to throw an exception. To determine what the maximum possible target speed for the motor is, use the max_speed method.

Note

Note that for this method to move the wheel the expected distance, the correct wheel_diameter value needs to be used.

Parameters:

target_speed (int or float) – Desired speed in m/s

direction (Direction) – Direction to rotate the motor. Defaults to forward.

distance (int or float) – Total distance to travel in m. Set to 0 to run indefinitely.

stop()[source]

Stop the motor in all circumstances.

target_rpm()[source]

Get the desired RPM of the motor output shaft, assuming the user is controlling the motor using set_target_rpm (motor is in control mode 1).

If this is not the case, returns None.

torque_limited

Check if the actual motor speed or RPM does not match the target speed or RPM.

Returns a boolean value, True if the motor is torque- limited and False if it is not.

wheel_circumference

wheel_diameter

Represents the diameter of the wheel attached to the motor in meters.

This parameter is important if using library functions to measure speed or distance, as these rely on knowing the diameter of the wheel in order to function correctly. Use one of the predefined pi-top wheel and tyre types, or define your own wheel size.

Note

Note the following diameters:

pi-top MMK Standard Wheel: 0.060.0m

pi-top MMK Standard Wheel with Rubber Tyre: 0.065m

pi-top MMK Standard Wheel with tank track: 0.070m

Parameters: wheel_diameter (int or float) – Wheel diameter in meters.

6.3.1. Parameters

classpitop.pma.parameters.BrakingType[source]

Braking types.

BRAKE= 1

COAST= 0

classpitop.pma.parameters.ForwardDirection[source]

Forward directions.

CLOCKWISE= 1

COUNTER_CLOCKWISE= -1

classpitop.pma.parameters.Direction[source]

Directions.

BACK= -1

FORWARD= 1

.END

Using I2C and SPI for LCD Display, MPU6050 etc