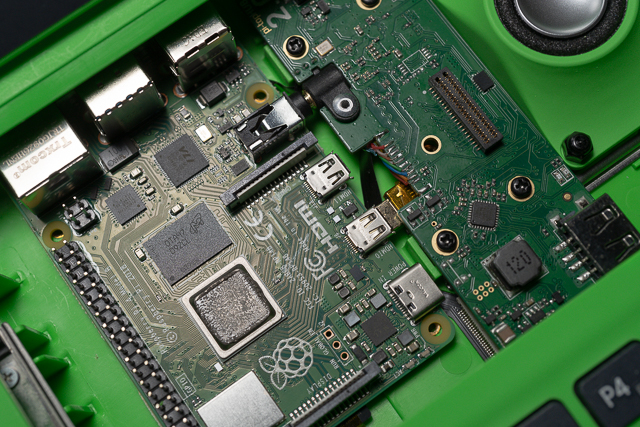

That still looks awesome! I think you may still be able to use the pi-topSpeaker as it can also take HDMI audio from the single board computer and turn it into I2S Audio via the hub.

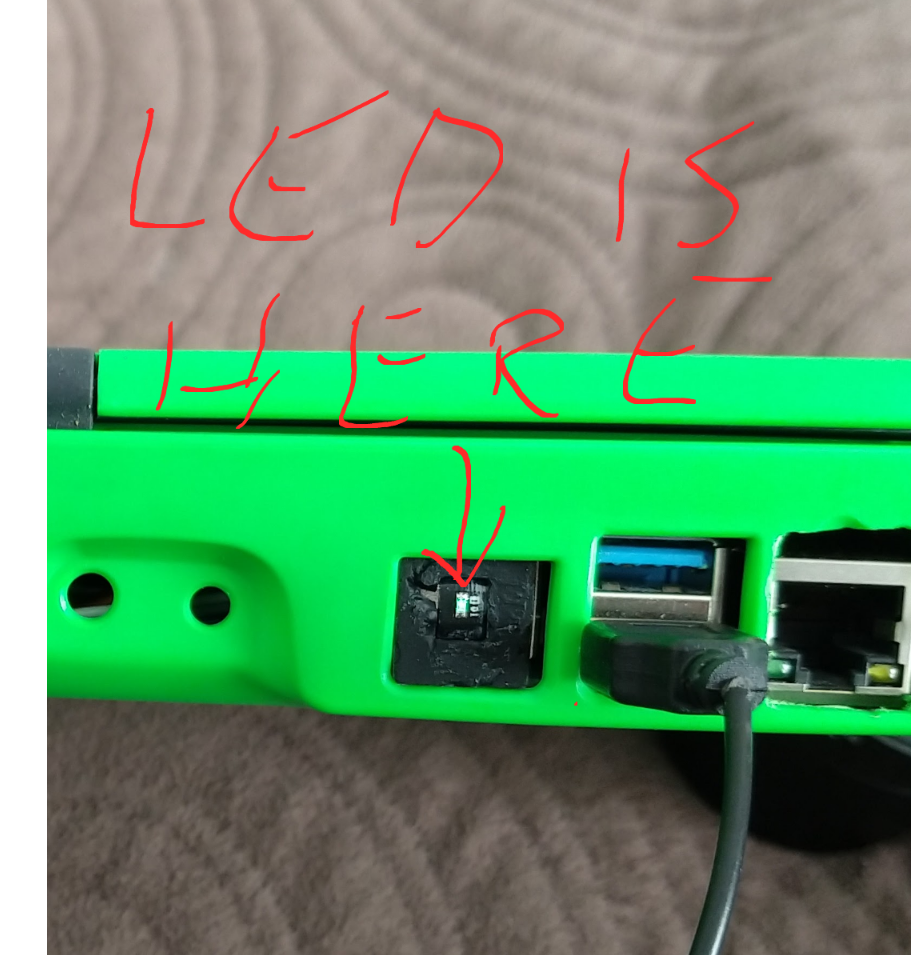

RE the battery: RPi OS had a package you could install in order to get the battery indicator working on just regular though I can’t seem to find it anymore.

There’s this forum post discussing it

https://www.raspberrypi.org/forums/viewtopic.php?t=204021

Do let us know if you can get it working though!

-RezIN

I got an iFixit set so should hopefully be able to carefully release the FPCB from the chassis in order to move the USB plugs into position for the RPi4’s USB2 ports. What did you use to release it?

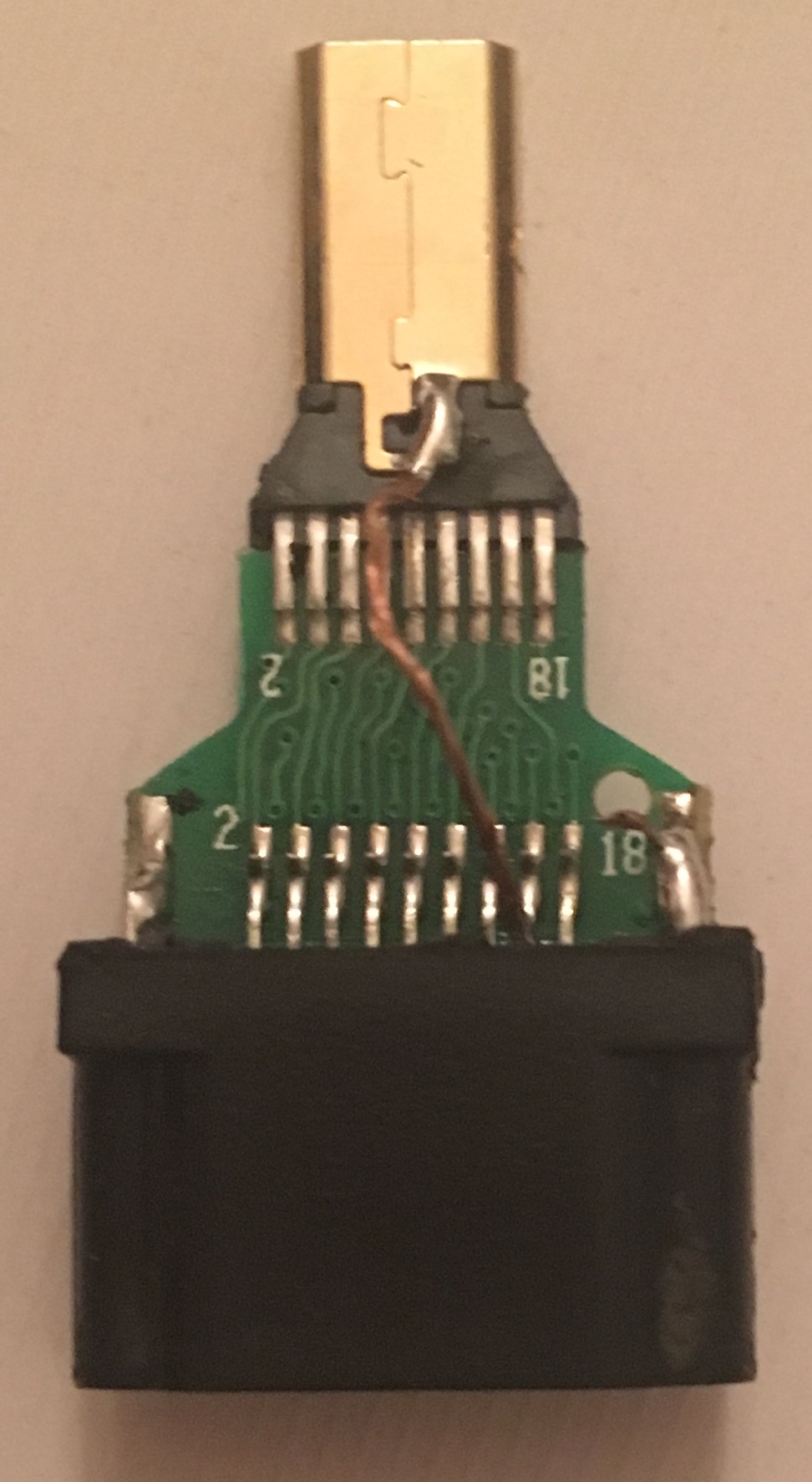

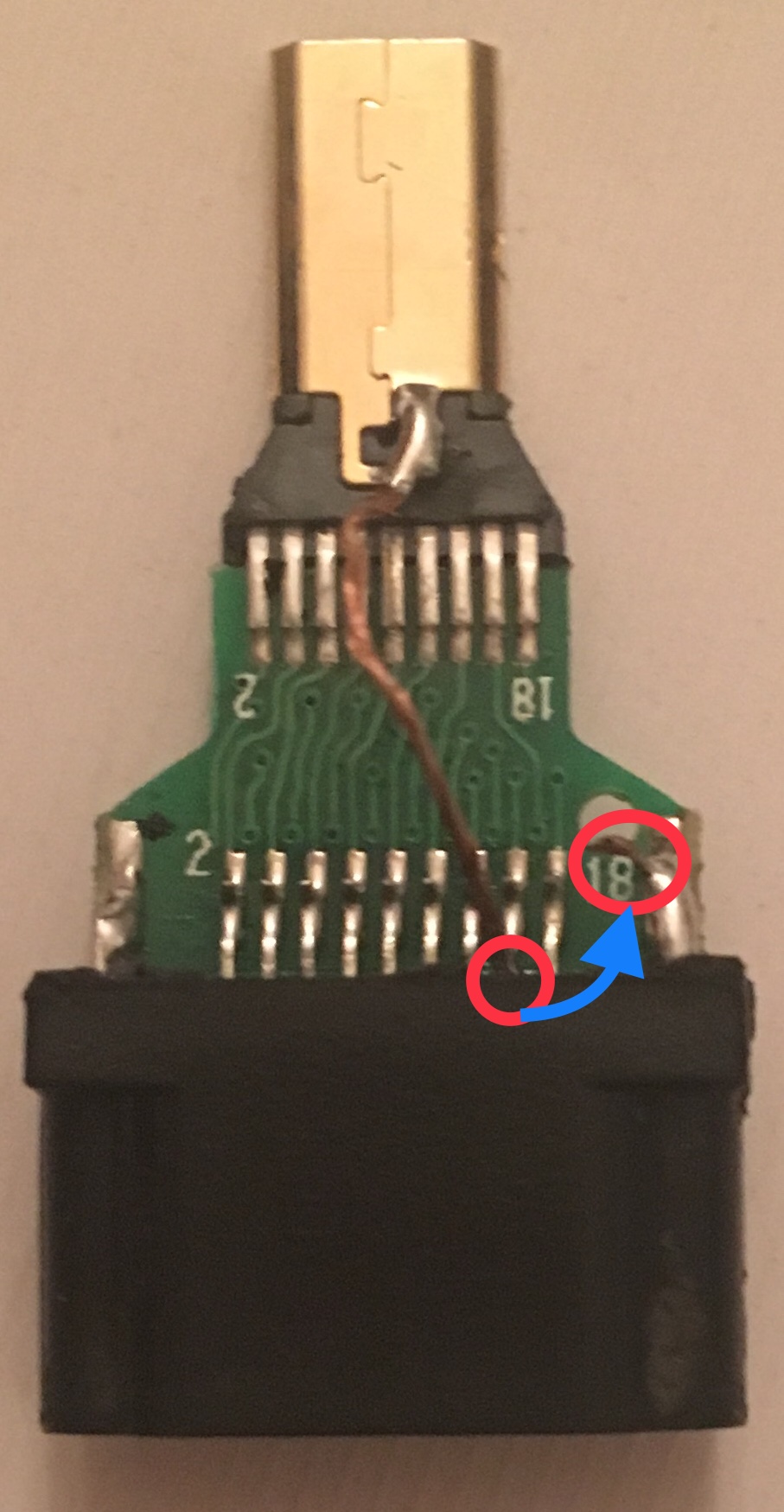

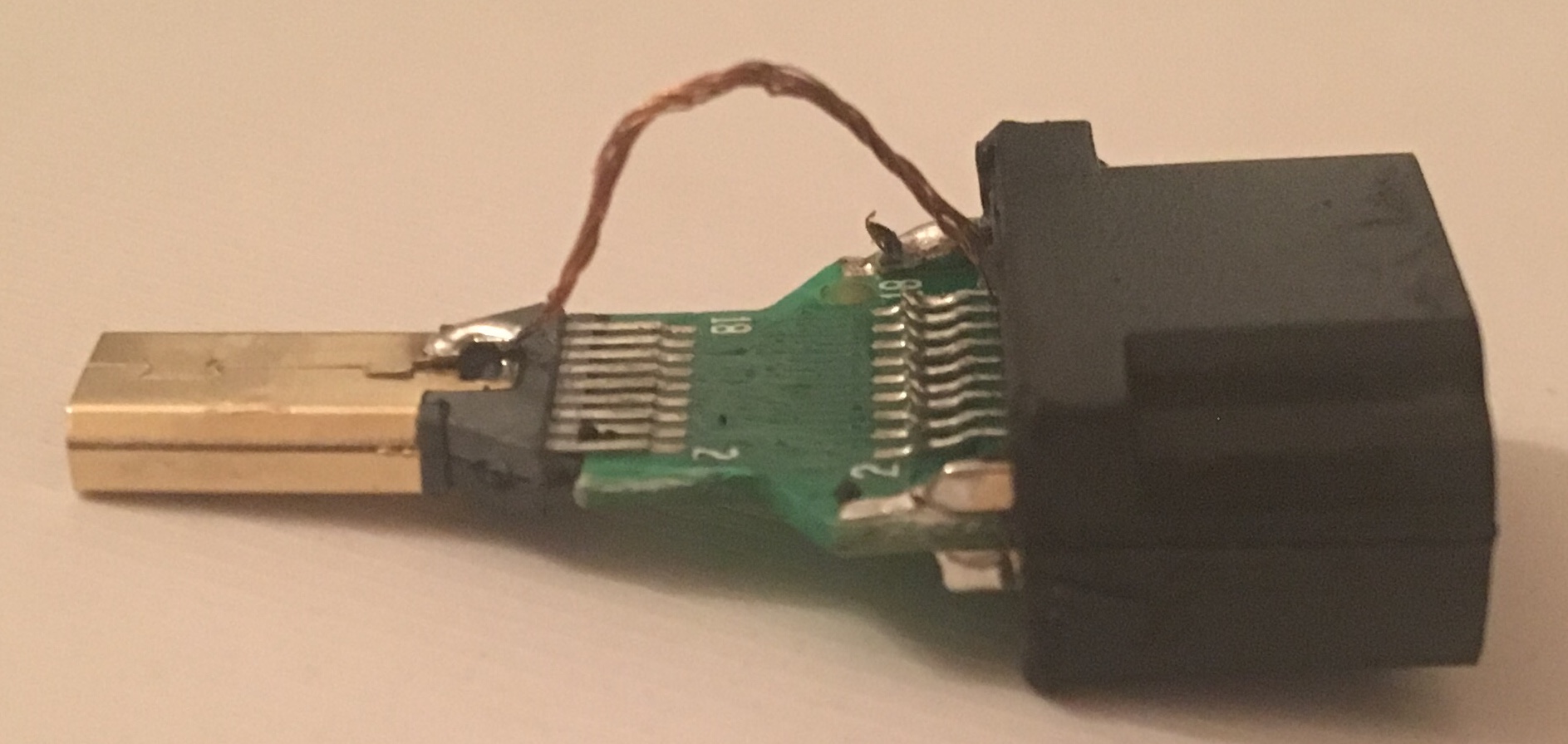

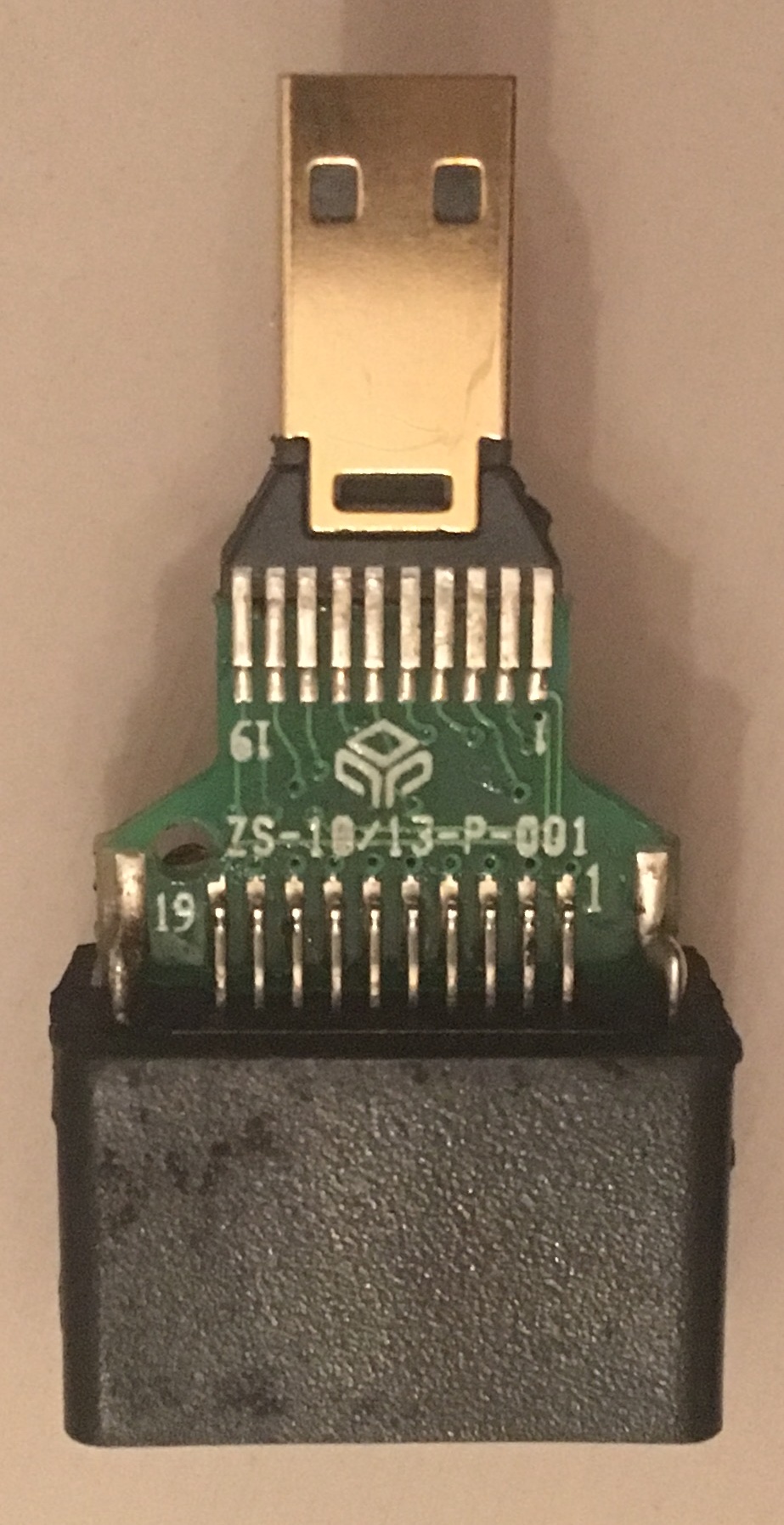

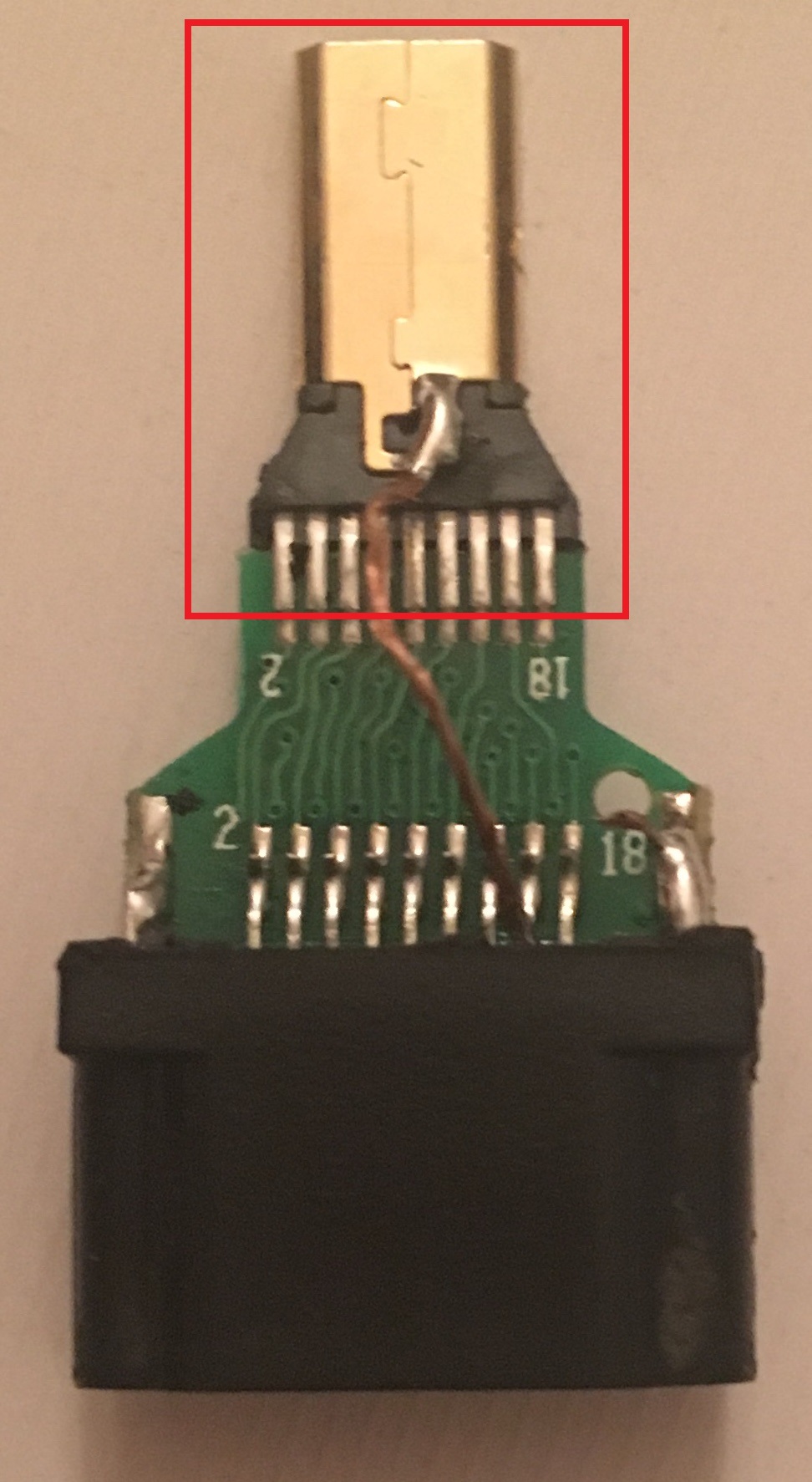

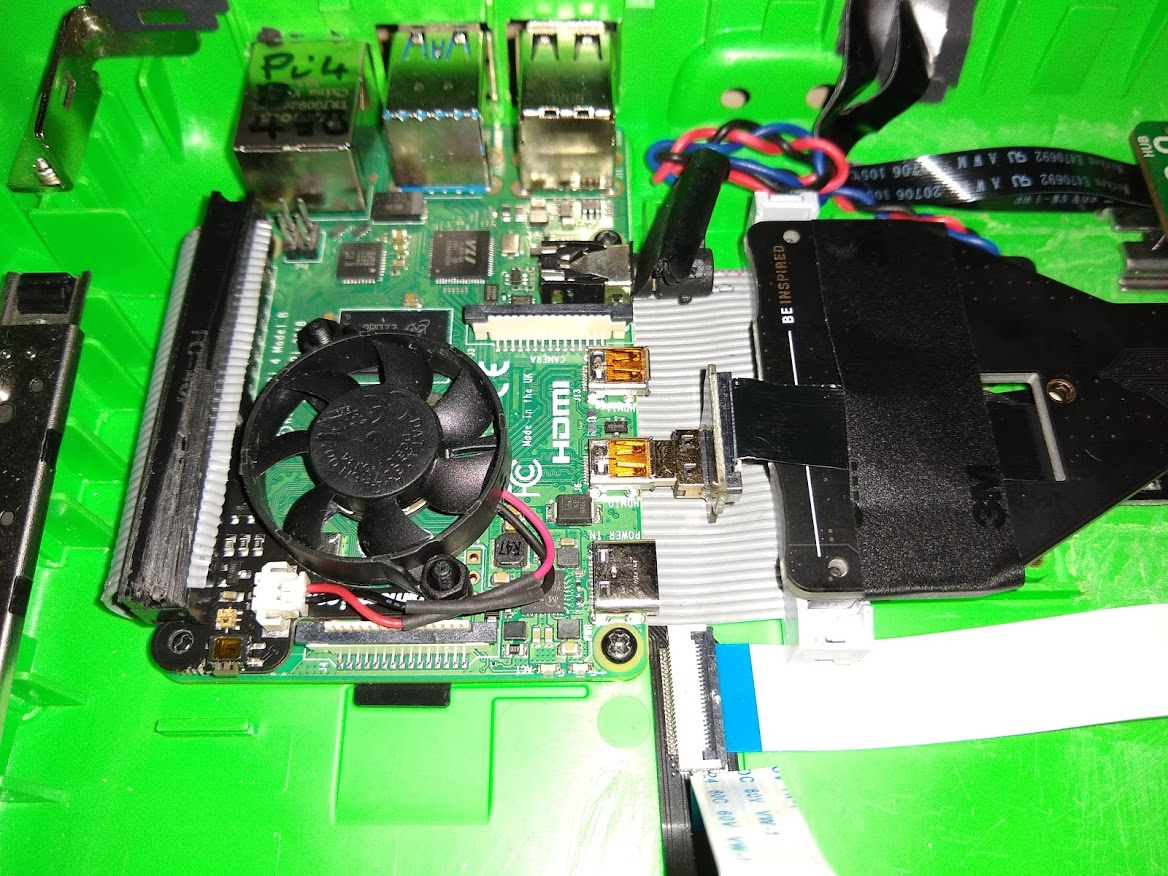

I got an iFixit set so should hopefully be able to carefully release the FPCB from the chassis in order to move the USB plugs into position for the RPi4’s USB2 ports. What did you use to release it? However, I’ve been reading up on (de)soldering SMT by hand and, with a bit of care, the techniques don’t sound too much more difficult… My plan is to have two Hubv2’s, one in the original RPi3B+ config and one in the RPi4 config so I can hotswap them interchangeably; that way I can still use RPi3-only OSes (like my old copy of pi-top Polaris) when I want.

However, I’ve been reading up on (de)soldering SMT by hand and, with a bit of care, the techniques don’t sound too much more difficult… My plan is to have two Hubv2’s, one in the original RPi3B+ config and one in the RPi4 config so I can hotswap them interchangeably; that way I can still use RPi3-only OSes (like my old copy of pi-top Polaris) when I want.